The composite rollers market is witnessing significant growth, driven by advancements in materials science, increasing demand for lightweight and durable components, and a growing emphasis on sustainability. Composite rollers, made from materials such as carbon fiber, fiberglass, and thermoplastics, offer several advantages over traditional metal rollers, including reduced weight, enhanced durability, and improved performance in various industrial applications. As industries continue to evolve, several key trends are shaping the future of the composite rollers market.

According to Stratview Research, the composite rollers market was estimated at USD 140.86 million in 2022 and is likely to grow at a CAGR of 5.09% during 2023-2028 to reach USD 190.39 million in 2028.

- Technological Advancements: Innovations in composite materials and manufacturing processes are at the forefront of the market's growth. Advanced techniques such as automated fiber placement (AFP) and resin transfer molding (RTM) are improving the quality and consistency of composite rollers. These technologies enable the production of rollers with superior strength, precision, and performance, meeting the stringent requirements of modern industrial applications.

- Increased Demand for Lightweight Solutions: Industries such as automotive, aerospace, and packaging are increasingly seeking lightweight solutions to enhance operational efficiency and reduce energy consumption. Composite rollers, being significantly lighter than their metal counterparts, contribute to reduced inertia, lower energy costs, and improved handling. This trend is particularly prominent in the automotive and aerospace sectors, where weight reduction is critical for fuel efficiency and performance.

- Emphasis on Sustainability: Sustainability is becoming a key focus for industries worldwide. Composite rollers, with their longer lifespan and lower maintenance requirements, align with the sustainability goals of many companies. Additionally, the development of eco-friendly composite materials and recycling processes is gaining traction, further enhancing the environmental benefits of composite rollers.

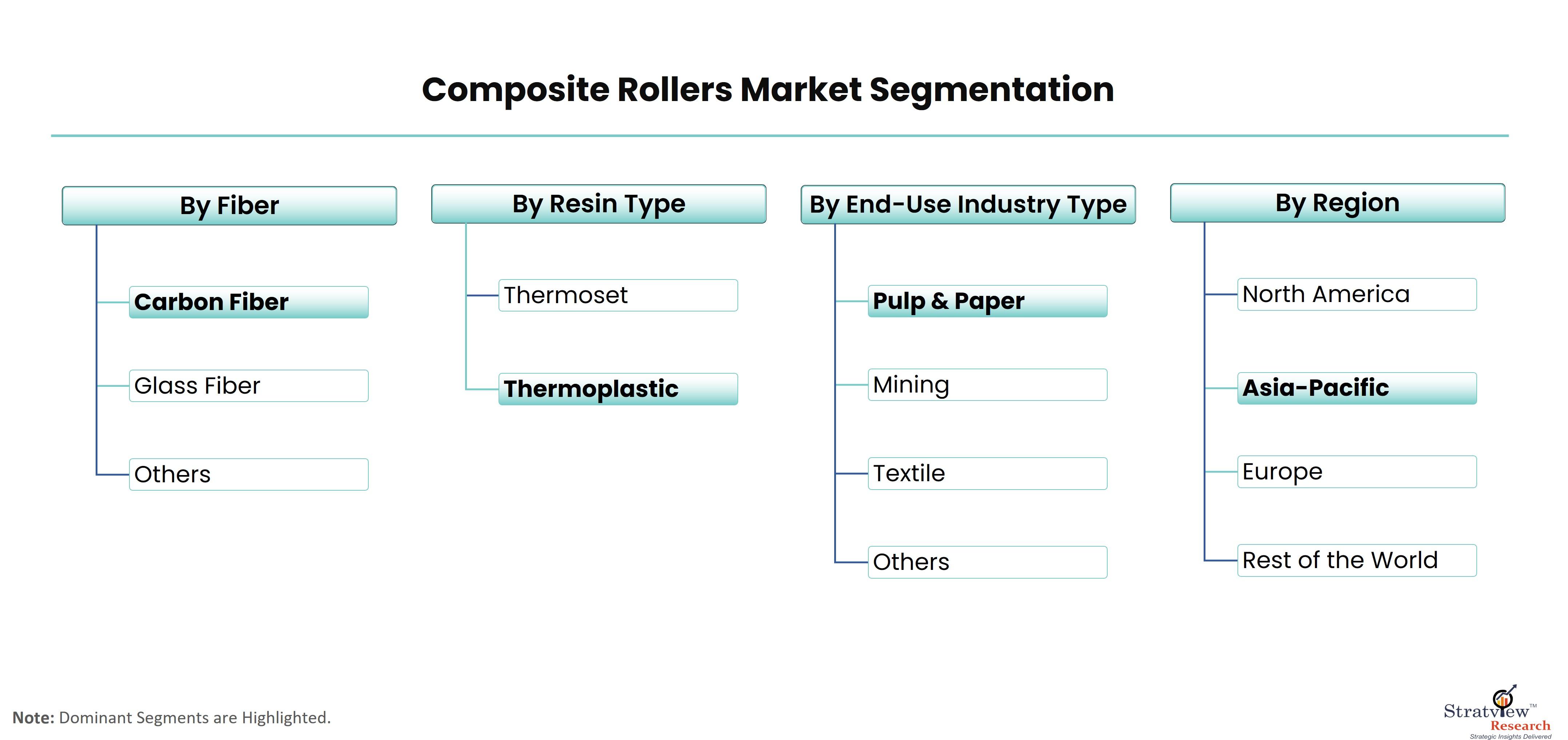

- Diversification of Applications: While composite rollers have traditionally been used in industries such as paper and pulp, textiles, and mining, their applications are diversifying. Emerging sectors such as renewable energy, electronics, and food processing are increasingly adopting composite rollers due to their unique properties. This diversification is driving market expansion and creating new opportunities for manufacturers.

- Growing Adoption in Emerging Markets: The rapid industrialization and infrastructure development in emerging economies, particularly in Asia-Pacific and Latin America, are fueling the demand for composite rollers. These regions are investing heavily in modernizing their manufacturing capabilities, leading to increased adoption of advanced materials and technologies, including composite rollers.

- Enhanced Performance Requirements: As industries push the boundaries of performance, the demand for high-precision, durable, and reliable components is rising. Composite rollers, with their ability to withstand harsh environments, high speeds, and heavy loads, are meeting these enhanced performance requirements. This trend is particularly evident in sectors such as mining, where operational efficiency and equipment longevity are paramount.

Conclusion: The future of the composite rollers market is promising, driven by technological advancements, the demand for lightweight and sustainable solutions, and the diversification of applications. As industries continue to evolve and prioritize efficiency and sustainability, the adoption of composite rollers is set to increase, offering numerous opportunities for growth and innovation in the market. Manufacturers and stakeholders must stay abreast of these key trends to capitalize on the evolving market dynamics and drive the future of composite roller technology.