Within the rapidly changing environment of warehouse and logistics operations, the efficiency and effectiveness of material handling equipment become very important. One type of stacker that is the hybrid solution, narrowing or bridging the gap between a manual and a full electric model, is the semi-electric stacker.

How does it work?

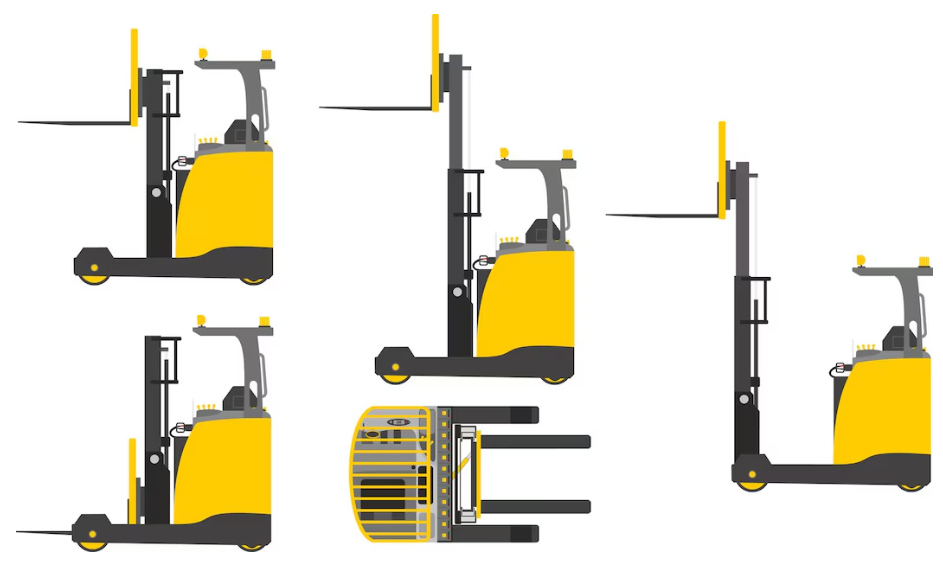

Semi-electric stackers are different from manual stackers in that they run from a mix of human and electric power. This means that the electric motor provides power to the lifting mechanism while travel is by manual push or pull. In this regard, they offer a very interesting blend of cost-effectiveness, ergonomics, and flexibility of operation.

Advantages of Semi-Electric Stackers

Cost-Effective: Semi-electric stackers are more pocket-friendly compared to models that are fully electric; hence, quite alluring to most businesses with varying magnitude of operations and budget.

Ergonomically Designed: Semi electric stacker reduces much the physical stress on the operator through automatic lifting that makes a great deal in improving safety and productivity of the workforce.

Flexibility: The machines can be used in electric and manual modes; hence, they have versatility for different work environments and tasks.

Maneuverability: Because they are compact and lightweight, they easily operate in small spaces to achieve optimal warehouse layout and utilization.

Environmentally Friendly: Though not as "green" as the full electric stackers, a semi-electric stacker still holds some advantages of carbon emissions compared to their manual counterpart.

Ideal Applications

A semi-electric stacker finds its place in various industries and applications, including the following:

Warehousing and Distribution Centers: To handle pallets and boxes during storage and retrieval operations.

Manufacturing Facilities: Moving materials and components around production lines.

Retail Stores: Loading and offloading merchandise.

Logistics and Transportation: Assisting in loading and offloading processes.

Challenges and Considerations

Though there are several advantages of semi-electric stackers, it is prudent to mention their drawbacks as well:

Operator Dependence: Horizontal movement remains dependent on manual power and, hence can be physically draining for the operators.

Lifting Capacity: Semi-electric stackers may have a limited lifting capacity than the fully electric ones, and hence cannot be used for heavy loads.

Proper care of the batteries will guarantee perfect running and a longer life. The future of Semi powered stacker

Within a few years, we expect significant improvement in semi-powered stacker designs and features. With lithium-ion batteries, regenerative braking, and intelligent control systems, these trucks could become more efficient and user-friendly.

Summary:

Semi-electric stackers can offer an economical yet effective solution to manage material handling efficiently without running into very high costs for a business. Carefully considering the needs and operational requirements in using them, companies will be in a position to decide whether a semi electric stacker is just what their operation requires.