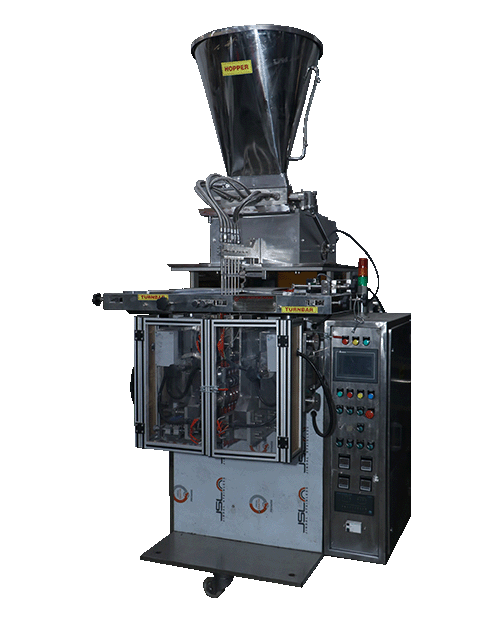

Durga Packaging Machine Choosing the right oil packing machine is crucial for ensuring efficiency, accuracy, and safety in the packaging process. Whether you are in the food, cosmetic, or industrial sector, selecting an oil packing machine that meets your specific needs can significantly impact your production quality and output. Here are the top features to look for in an oil packing machine:

1. High Accuracy and Precision

Accuracy in filling and packing is essential to avoid wastage and ensure consistent product quality. Look for an oil packing machine equipped with advanced sensors and control systems that guarantee precise filling volumes. This feature is particularly important for products sold by weight or volume, where inconsistencies can lead to customer dissatisfaction and regulatory issues.

2. Versatility and Flexibility

An ideal oil packing machine should handle various types of oils, including edible oils, lubricants, and essential oils. It should also be adaptable to different packaging materials, such as bottles, pouches, or cans. Versatility allows you to diversify your product line without investing in multiple machines, making it a cost-effective choice for growing businesses.

3. Speed and Efficiency

Production speed is a critical factor in meeting market demands and optimizing operational efficiency. Evaluate the machine’s throughput capacity, ensuring it aligns with your production goals. High-speed oil packing machines can significantly reduce downtime and increase overall productivity, making them a valuable asset for high-volume operations.

4. User-Friendly Interface

A user-friendly interface simplifies operation and minimizes the need for extensive training. Look for machines with intuitive touchscreens, easy-to-understand controls, and clear display panels. Features such as automated cleaning and maintenance alerts can also enhance user experience and reduce the risk of operational errors.

5. Durability and Robust Construction

The construction quality of the oil packing machine directly affects its longevity and reliability. Choose machines made from high-quality, corrosion-resistant materials, such as stainless steel. Robust construction ensures the machine can withstand the rigors of continuous operation and harsh production environments, providing long-term value and reducing maintenance costs.

6. Safety Features

Safety should be a top priority in any packaging operation. Ensure the oil packing machine is equipped with essential safety features, such as emergency stop buttons, overload protection, and safety guards. Compliance with industry safety standards not only protects your workforce but also ensures uninterrupted production.

7. Automated Features and Integration Capabilities

Automation enhances efficiency by reducing the need for manual intervention. Look for oil packing machines with automated features like bottle positioning, capping, labeling, and batch coding. Additionally, integration capabilities with other packaging line equipment, such as conveyors and labeling machines, streamline the production process and improve overall workflow.

8. Customizability

Every business has unique packaging requirements. Opt for an oil packing machine that offers customization options to tailor the machine’s functionality to your specific needs. This may include adjustable filling nozzles, customizable control settings, and modular components that can be easily upgraded or replaced.

9. Energy Efficiency

Energy-efficient machines not only reduce operational costs but also contribute to sustainable business practices. Look for oil packing machines designed with energy-saving technologies, such as low power consumption motors and efficient heat sealing systems. These features can significantly lower your carbon footprint and enhance your company’s environmental responsibility.

10. After-Sales Support and Service

Reliable after-sales support is crucial for maintaining the performance and longevity of your oil packing machine. Choose manufacturers or suppliers that offer comprehensive support services, including installation, training, regular maintenance, and prompt troubleshooting assistance. Access to spare parts and technical support ensures minimal downtime and continuous production.

Conclusion

Investing in the right oil packing machine is essential for optimizing your packaging operations and ensuring product quality. By prioritizing features such as accuracy, versatility, speed, user-friendliness, durability, safety, automation, customizability, energy efficiency, and reliable after-sales support, you can select a machine that meets your business needs and enhances your production capabilities. An oil packing machine with these top features will not only streamline your operations but also contribute to the overall success and growth of your business.

Durga Packaging Machine is India's leading manufacturer of Oil Packing Machine. You can contact them for further information regarding the Oil Packing Machine at