Introduction

Chloroquine phosphate is a critical medication used primarily in the treatment of malaria and certain autoimmune diseases like rheumatoid arthritis and lupus. With its significance in global health, establishing a manufacturing plant for chloroquine phosphate presents a valuable business opportunity. This Chloroquine Phosphate Manufacturing Plant Project Report provides a comprehensive guide for establishing a facility dedicated to producing chloroquine phosphate, a vital medication used in treating malaria and autoimmune diseases.

Project Scope

The primary objective of this project is to establish a facility that produces high-quality chloroquine phosphate. Key components of the project include:

- Market Research: Understanding market demand and competition.

- Location Selection: Choosing a strategic site for the plant.

- Facility Design: Planning the layout and infrastructure.

- Equipment Procurement: Acquiring necessary machinery and technology.

- Raw Materials: Sourcing essential ingredients and chemicals.

- Production Process: Implementing efficient methods for manufacturing chloroquine phosphate.

- Quality Control: Ensuring the final product meets industry standards.

- Financial Planning: Estimating costs and projecting revenues.

Read Full Report with Table of Contents @ https://www.expertmarketresearch.com/prefeasibility-reports/chloroquine-phosphate-manufacturing-plant-project-report/requestsample

Market Analysis

Before setting up the plant, a thorough market analysis is crucial. The global demand for chloroquine phosphate is influenced by several factors:

- Disease Prevalence: Malaria remains a significant health issue in many parts of the world, driving demand for chloroquine phosphate. Additionally, its use in treating autoimmune diseases contributes to its market need.

- Regulatory Environment: Compliance with health regulations and obtaining necessary approvals can impact market entry and operations.

- Competitive Landscape: Analyzing competitors and their market share helps in positioning your product effectively and identifying potential challenges.

Location Selection

Selecting the right location for the plant involves several key considerations:

- Proximity to Raw Materials: Being close to suppliers of raw materials can reduce transportation costs and ensure a steady supply.

- Infrastructure: The location should have adequate infrastructure, including transportation networks, utilities, and communication systems.

- Regulatory Compliance: Ensure that the location meets local health, safety, and environmental regulations.

- Labor Availability: Access to a skilled workforce is essential for efficient plant operations.

Facility Design

The design of the manufacturing facility should facilitate efficient production and ensure compliance with industry standards. Key aspects include:

- Raw Material Storage: Adequate storage facilities for raw materials to maintain quality and prevent contamination.

- Production Area: A layout that includes areas for chemical reactions, purification, and formulation. The design should support a smooth workflow and minimize downtime.

- Quality Control: Dedicated space for laboratories and testing equipment to monitor the quality of chloroquine phosphate throughout the production process.

- Administrative and Support Areas: Offices, staff rooms, and restrooms to ensure a functional and comfortable working environment.

Equipment Procurement

Investing in high-quality equipment is crucial for the efficient production of chloroquine phosphate. Essential machinery includes:

- Reaction Vessels: For chemical reactions involved in the synthesis of chloroquine phosphate.

- Purification Units: For separating and purifying the product.

- Drying Equipment: For drying the final product to achieve the desired consistency and purity.

- Packaging Machines: For packaging chloroquine phosphate in appropriate containers for distribution.

Production Process

The production of chloroquine phosphate typically involves several key stages:

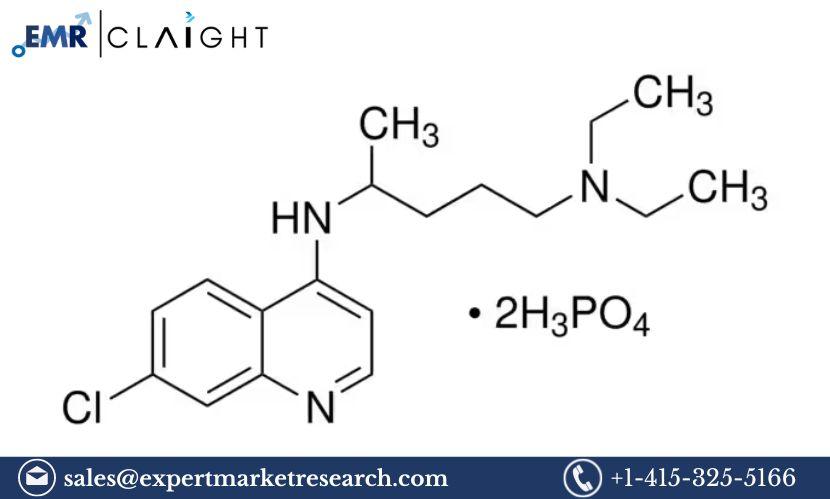

- Chemical Synthesis: The process begins with the synthesis of chloroquine base from precursor chemicals.

- Formation of Chloroquine Phosphate: The chloroquine base is then reacted with phosphoric acid to form chloroquine phosphate.

- Purification: The chloroquine phosphate is purified to remove impurities and ensure high quality.

- Drying: The purified product is dried to achieve the desired consistency.

- Formulation and Packaging: The final product is formulated into tablets or other dosage forms and packaged for distribution.

Quality Control

Maintaining high standards of quality is essential for the safety and efficacy of chloroquine phosphate. Implement rigorous quality control measures:

- Material Testing: Regularly test raw materials and finished products for purity and compliance with industry standards.

- Process Monitoring: Continuously monitor production processes to ensure they operate within the desired parameters.

- Regulatory Compliance: Adhere to guidelines and regulations set by health authorities and regulatory agencies.

Financial Planning

Financial planning involves several key considerations:

- Cost Estimation: Calculate costs for equipment, raw materials, labor, utilities, and maintenance.

- Revenue Projections: Estimate potential income based on market demand, pricing strategies, and sales forecasts.

- Funding Requirements: Identify sources of capital, such as loans or investment, to finance the project.

- Profitability Analysis: Assess the potential return on investment and long-term financial viability of the plant.

FAQs

What are the main raw materials required for manufacturing chloroquine phosphate?

The primary raw materials include precursor chemicals for chloroquine base and phosphoric acid. Additional materials might be required depending on the specific production process and formulation.

Why is the location of the plant important?

The location affects raw material costs, labor availability, infrastructure, and regulatory compliance. Choosing a strategic location can reduce costs, enhance operational efficiency, and ensure compliance with local regulations.

What equipment is needed for chloroquine phosphate production?

Essential equipment includes reaction vessels, purification units, drying equipment, and packaging machines. Each piece of equipment plays a crucial role in the production process, from chemical synthesis to final product packaging.

How is the quality of chloroquine phosphate ensured during production?

Quality is maintained through rigorous testing of raw materials and finished products, continuous monitoring of production processes, and adherence to industry standards and regulatory guidelines.

What financial factors should be considered when setting up a chloroquine phosphate manufacturing plant?

Key financial factors include the cost of equipment, raw materials, labor, utilities, and maintenance. Additionally, projecting revenue, securing funding, and analyzing profitability are essential for assessing the financial viability of the plant.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/