The Conveyor Oven Market revolves around the production, distribution, and application of conveyor ovens, which are industrial or commercial ovens that use a conveyor belt to transport products through a heated chamber. These ovens are widely used in food processing, electronics, automotive, and other industries for applications that require continuous, consistent cooking, heating, or drying.

Key Aspects of the Conveyor Oven Market:

-

Market Growth:

- The conveyor oven market is experiencing growth due to the rising demand for automated and efficient cooking solutions in the food industry, as well as the need for consistent and high-quality heating processes in industrial applications. The increasing adoption of automation in various sectors is a significant driver for this market.

-

Types of Conveyor Ovens:

- Gas Conveyor Ovens: These ovens use natural gas or propane as a heat source, offering quick heating and high temperature capabilities, making them suitable for high-volume cooking in commercial kitchens.

- Electric Conveyor Ovens: Powered by electricity, these ovens are preferred for their energy efficiency, precise temperature control, and cleaner operation, especially in industries where emissions need to be controlled.

- Infrared Conveyor Ovens: Utilize infrared radiation to heat products quickly and evenly, often used in applications requiring fast cooking or drying, such as in the food industry or for curing coatings.

- Radiant Heat Conveyor Ovens: Employ radiant heat to achieve uniform temperature distribution, commonly used in industries requiring consistent heat application across the product surface.

- Forced Convection Conveyor Ovens: These ovens use fans to circulate hot air, ensuring even temperature distribution and are popular in both food processing and industrial applications.

-

Applications:

- Food Industry: Conveyor ovens are extensively used in commercial kitchens, bakeries, and food processing plants for baking, cooking, roasting, and drying various food products like pizzas, breads, cookies, and meats.

- Electronics: In the electronics industry, conveyor ovens are used for soldering, curing adhesives, and drying components, where consistent and controlled heat application is critical.

- Automotive: Conveyor ovens are employed in the automotive sector for drying paints and coatings, curing adhesives, and heat-treating various components.

- Textiles: In textile manufacturing, conveyor ovens are used for drying fabrics, curing dyes, and heat-setting fibers.

- Pharmaceuticals and Chemicals: Used for drying, curing, and sterilizing products, ensuring consistency and compliance with industry standards.

-

Technology Trends:

- Automation and IoT Integration: The incorporation of automation and IoT technologies in conveyor ovens allows for real-time monitoring, control, and optimization of the cooking or heating process, improving efficiency and reducing operational costs.

- Energy Efficiency: Development of more energy-efficient conveyor ovens with advanced insulation, heat recovery systems, and precise temperature controls to reduce energy consumption and operating costs.

- Customizable Designs: Growing demand for customized conveyor ovens tailored to specific industrial needs, such as variable speed control, multi-zone heating, and specialized materials to handle different products and processes.

- Hygienic Design: In the food industry, there is an increasing focus on conveyor ovens with hygienic designs that are easy to clean and maintain, helping to meet strict food safety regulations.

-

Market Segmentation:

- By Type: Gas, electric, infrared, radiant heat, forced convection, and others.

- By Application: Food industry, electronics, automotive, textiles, pharmaceuticals, and others.

- By Belt Type: Wire mesh, solid, perforated, and others.

- By End-User: Commercial, industrial, and laboratory settings.

-

Regional Insights:

- North America: A significant market driven by the strong presence of food service chains, advanced manufacturing sectors, and a focus on automation and energy efficiency.

- Europe: The market is supported by the region’s robust food processing industry, stringent regulations on food safety, and advanced automotive and electronics industries.

- Asia-Pacific: The fastest-growing market, fueled by rapid industrialization, the expansion of the food service industry, and increasing adoption of automation in manufacturing processes, particularly in China, India, and Japan.

- Latin America and the Middle East & Africa: Emerging markets with growing food processing industries, expanding industrial base, and increasing investments in manufacturing and automation technologies.

-

Market Drivers:

- Increasing Demand for Processed Foods: The growing consumption of processed and ready-to-eat foods is driving the demand for conveyor ovens in the food industry, where efficiency and consistency are key.

- Rising Adoption of Automation: Across various industries, the shift towards automated production processes is boosting the demand for conveyor ovens that offer consistent and controlled heating.

- Energy Efficiency and Cost Savings: The focus on reducing energy consumption and operational costs is pushing the demand for advanced conveyor ovens that are more energy-efficient and require less manual intervention.

- Stringent Food Safety Regulations: In the food industry, compliance with safety and hygiene standards is driving the adoption of conveyor ovens that are easy to clean and maintain.

-

Challenges:

- High Initial Investment: The cost of acquiring and installing conveyor ovens, especially advanced models with automation and IoT capabilities, can be prohibitive for small and medium-sized enterprises.

- Maintenance and Downtime: Conveyor ovens require regular maintenance to ensure optimal performance, and any downtime can lead to significant losses, particularly in high-volume production environments.

- Customization Needs: Different industries and applications may require highly customized conveyor ovens, which can increase lead times and costs for manufacturers.

- Energy Costs: Despite advancements in energy efficiency, the operational costs of running conveyor ovens, particularly gas models, can be high, especially in regions with expensive energy supplies.

-

Key Players:

- Leading companies in the conveyor oven market include Middleby Corporation, Lincoln Electric Holdings, Inc., ITW Food Equipment Group, Davron Technologies, Inc., Star Manufacturing International, Inc., Wisconsin Oven Corporation, and Doyon Equipment Inc. These companies are known for their innovation, quality, and ability to provide customized solutions for various industries.

-

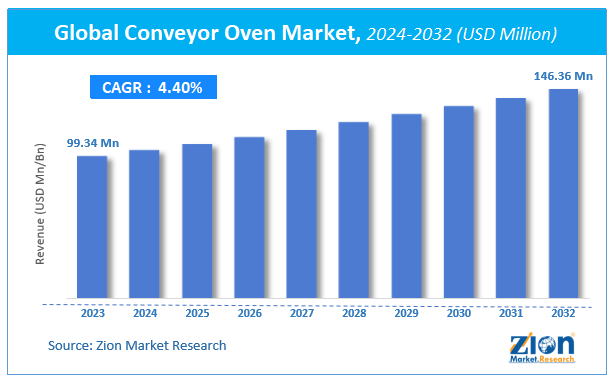

Market Outlook:

- The conveyor oven market is expected to grow steadily, driven by the ongoing demand for automated and efficient cooking and heating solutions in the food industry, as well as the expanding use of conveyor ovens in industrial applications. Technological advancements, particularly in automation, energy efficiency, and IoT integration, will shape the future of this market. Additionally, the growing focus on food safety and hygiene, particularly in the wake of global health concerns, will further drive the demand for advanced conveyor ovens in the food processing sector.

The market will continue to evolve with innovations that enhance performance, reduce energy consumption, and meet the specific needs of various industries.

Contact :

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: [email protected]

read other reports :

https://www.linkedin.com/pulse/2028-latest-report-dental-periodontics-market-size-business-wyqaf

https://www.linkedin.com/pulse/media-monitoring-software-market-newest-report-size-booming-imh3f

https://www.linkedin.com/pulse/kids-tablet-market-size-latest-reports-business-h9j5f