The extruded polypropylene (XPP) foam market is witnessing steady growth, fueled by its increasing adoption across various industries such as automotive, packaging, and construction. Known for its lightweight, durable, and eco-friendly properties, extruded polypropylene foam is becoming a preferred material for numerous applications. However, as the market expands, it faces both significant challenges and promising opportunities.

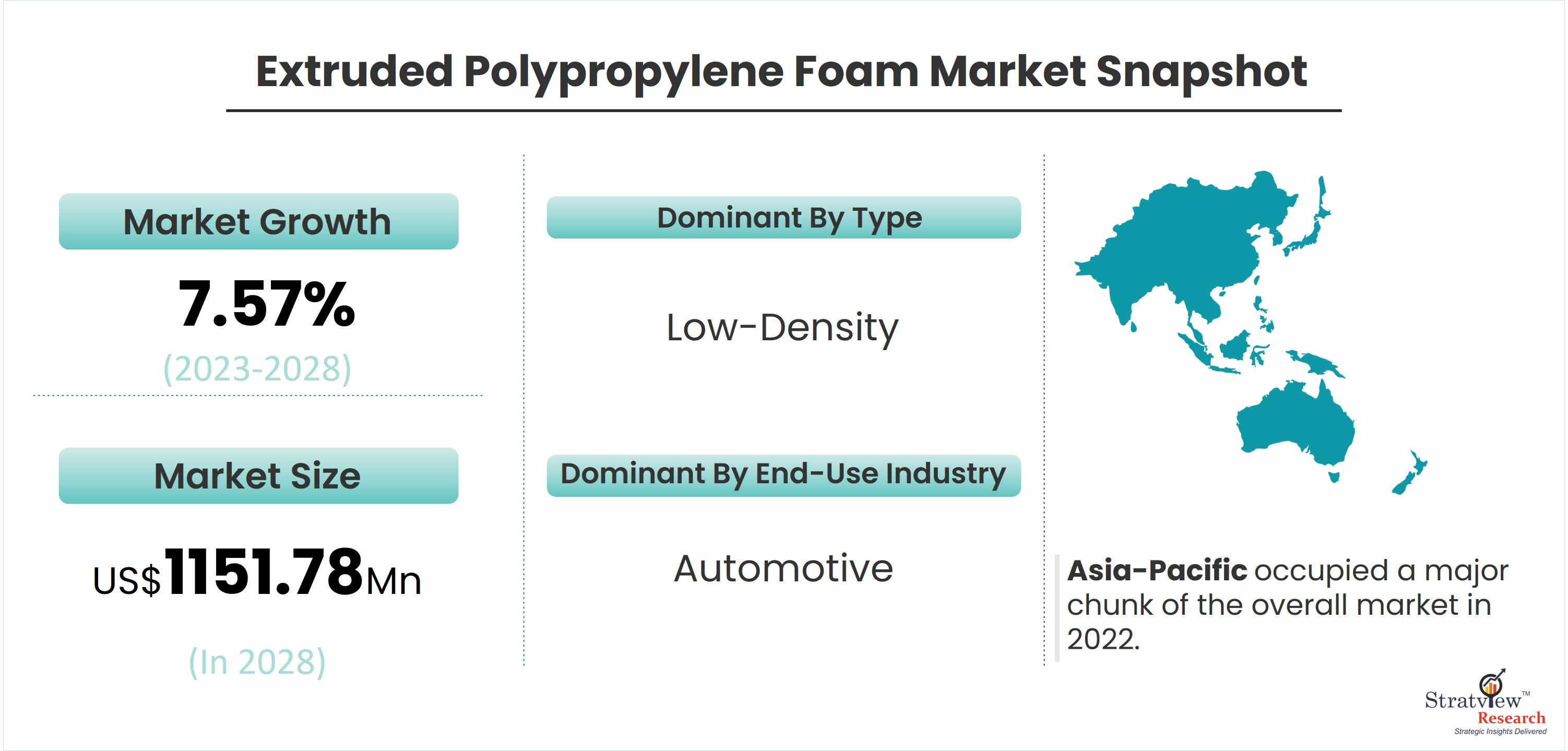

According to Stratview Research, the extruded polypropylene foam market was estimated at USD 738.74 million in 2022 and is likely to grow at a CAGR of 7.57% during 2023-2028 to reach USD 1151.78 million in 2028.

Opportunities Driving Market Growth

- Rising Demand for Lightweight Materials- One of the key opportunities in the extruded polypropylene foam market is the growing demand for lightweight materials, particularly in the automotive and aerospace industries. extruded polypropylene foam’s lightweight nature helps reduce vehicle weight, which enhances fuel efficiency and lowers emissions. With governments worldwide enforcing stricter environmental regulations, manufacturers are increasingly turning to extruded polypropylene foam to meet these requirements. The push for electric vehicles (EVs) further fuels demand, as EV manufacturers seek materials that can optimize battery performance and extend vehicle range.

- Sustainability and Environmental Benefits- The focus on sustainability is opening new avenues for extruded polypropylene foam in various sectors. As the world shifts towards eco-friendly products, extruded polypropylene foam’s recyclability makes it an attractive choice. Its ability to be reused and recycled aligns with the growing demand for circular economy solutions. Additionally, the development of bio-based polypropylene foams offers opportunities for innovation in green materials, allowing manufacturers to meet environmental goals while maintaining performance standards.

- Technological Advancements- Advancements in foam extrusion technologies are improving the quality, flexibility, and application of extruded polypropylene foam. These innovations are allowing manufacturers to produce foam with enhanced properties, such as increased thermal resistance, better impact absorption, and greater versatility. This has led to new applications in industries like healthcare, electronics, and sports equipment, presenting fresh growth prospects for the extruded polypropylene foam market.

Challenges Hindering Market Expansion

- High Production Costs- Despite its many advantages, one of the major challenges in the extruded polypropylene foam market is the high cost of production. The complexity of the extrusion process and the need for specialized equipment contribute to elevated manufacturing expenses. This cost barrier limits the adoption of extruded polypropylene foam, particularly in price-sensitive industries, where cheaper alternatives such as expanded polystyrene (EPS) or polyethylene foams are still widely used.

- Competition from Alternative Materials- The extruded polypropylene foam market faces strong competition from other foams and polymers. Materials like EPS, expanded polypropylene (EPP), and polyethylene foams are well-established and often cheaper, making it difficult for extruded polypropylene foam to gain market share in certain sectors. This competitive landscape forces extruded polypropylene foam manufacturers to focus on differentiating their products through performance improvements and sustainable innovations.

- Fluctuating Raw Material Prices- Volatility in the prices of raw materials, particularly polypropylene, poses a significant challenge for the extruded polypropylene foam market. The price fluctuations are influenced by various factors, including global supply chain disruptions, crude oil prices, and geopolitical tensions. These fluctuations can impact the overall cost structure for manufacturers, affecting profit margins and pricing strategies.

Conclusion

The extruded polypropylene foam market is poised for growth, driven by its sustainability, versatility, and alignment with industry trends like lightweighting and eco-friendly materials. However, it must overcome challenges such as high production costs and competition from alternative materials. The future of the market will likely be shaped by continued technological advancements, strategic investments in sustainability, and efforts to reduce production costs. By navigating these challenges, the extruded polypropylene foam market is well-positioned to capitalize on emerging opportunities across multiple industries.