A large molecule known as a polymer is made up of numerous monomeric building pieces that repeat. Polymers come in two varieties: natural and artificial. Synthetic polymers are produced through the polymerization of monomers, whereas natural polymers, such as resins, rubber, and gum, are generated from organic components.

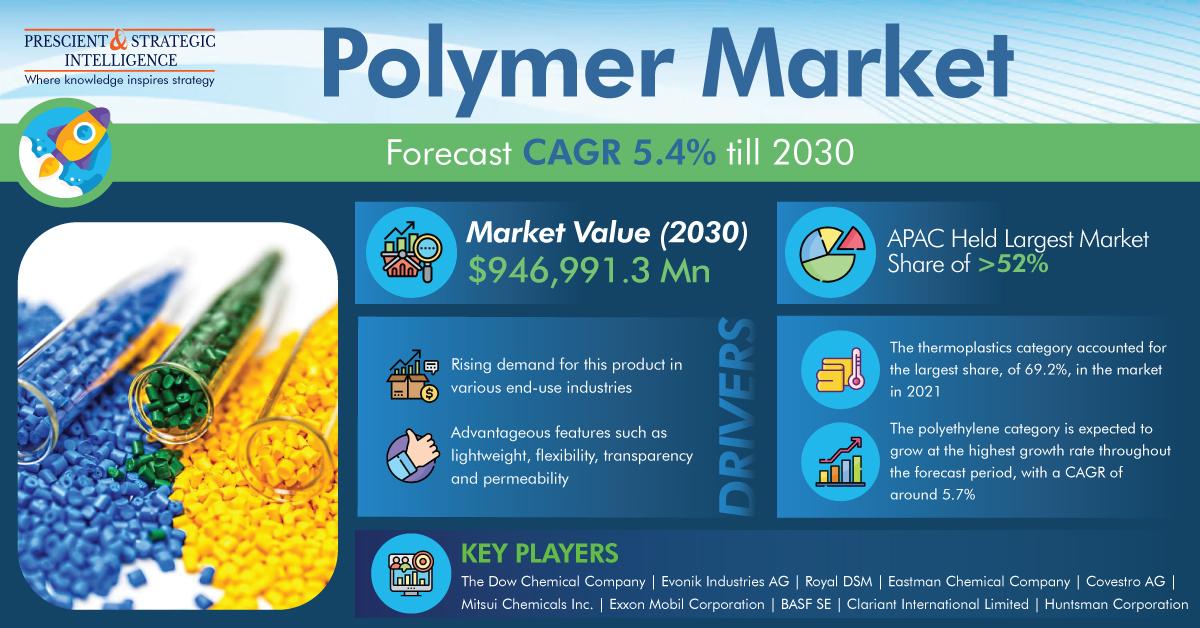

According to P&S Intelligence, the worldwide polymer market is anticipated to reach $946,991.38 million by 2030. This is mostly due to the product's rising demand across a variety of end-use sectors, including automotive, packaging, and electronics.

Increased Use of Alternative Materials in the Automotive Industry

In the production sectors of the automotive and other industries, the use of lightweight elements as an alternative to traditional materials like metals and ceramics has grown.

Their exceptional mechanical, electrical, and chemical qualities, including their elasticity, strength-to-weight ratio, insulating and optical characteristics, and corrosion resistance, are largely responsible for this.

Additionally, it is predicted that a 10% decrease in vehicle weight results in a proportionate decrease in fuel consumption, which promotes the high volumetric use of polymer in cars.

Polyethylene Demand Is Increasing, Driving the Industry

With a CAGR of about 5.7%, the polyethylene category is predicted to have the fastest increase in the coming years. This is explained by the rising need for the product across various end-use industries.

The market expansion in this sector is also fueled by the growing use of high- and low-density polyethylene in the packaging of foods and beverages including fruit juices, milk, and other food items.

Putting More Emphasis on Bio-Based Polymers

"Bio-based" refers to plastics generated from renewable biological resources, such as ethylene, which may be made from sugar cane and used to make polyethylene. Starch may be processed to create polylactic acid and lactic acid.

For reducing global carbon emissions, overall energy usage, and environmental protection, a bio-based polymer is excellent. Many firms are adopting this amazing plastic replacement since it helps both consumers and the packaging sector.

It's also crucial to understand that bio-based polymers including bio-based polyethylene contain sustainable carbon elements. This is one of the main reasons why many businesses are switching from polymers made of fossil sources to those made of biomaterials.

Additionally, bio-based plastics do not add any fresh carbon to the environment since, after their life cycles, they return to the atmosphere.

Majority of Revenue Comes from Thermoplastics

The thermoplastics category held the biggest market share, with 69.2%. This is explained by the growing demand for thermoplastics in the food industry, which is driven by their low cost, great mechanical strength, and simplicity of production.

The need for thermoplastics has also increased as a result of similar qualities in other fields, such as the manufacture of storage tanks, lightweight constructions, and window panels and frames.

Get More Details Polymer Market Growth Analysis