Introduction to Galvo Laser Engravers

A galvo laser engraver is a highly advanced tool used in various industries for precise marking and engraving tasks. Unlike traditional laser systems, the galvo laser engraver utilizes galvanometer-driven mirrors to direct the laser beam with exceptional accuracy and speed. This unique technology significantly enhances the efficiency and quality of engraving, making it a preferred choice for high-precision applications. In this article, we'll explore the intricacies of galvo laser engravers, their advantages, and their applications across different sectors.

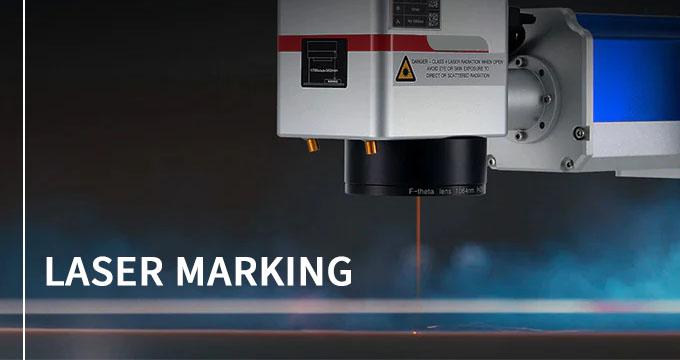

How Galvo Laser Engravers Work

The core technology behind a galvo laser engraver involves the use of galvanometer mirrors. These mirrors are controlled electronically to direct the laser beam swiftly across the surface of the material being engraved. The galvo laser engraver system employs rapid mirror movements to achieve high-speed engraving while maintaining accuracy. This setup contrasts with traditional laser systems that use mechanical movement of the entire laser head, resulting in slower processing times.

Advantages of Using a Galvo Laser Engraver

One of the primary benefits of a galvo laser engraver is its speed. Due to the fast-moving mirrors, this type of engraver can achieve high processing speeds, making it ideal for applications that require quick turnaround times. Additionally, the precision of a galvo laser engraver allows for detailed and intricate designs that would be challenging to achieve with other types of engraving machines. The reduced mechanical wear and tear also contribute to the longevity and reliability of the galvo laser engraver.

Applications of Galvo Laser Engravers

Galvo laser engravers are versatile tools used in various industries. In the manufacturing sector, they are employed for marking serial numbers, logos, and barcodes on products. The medical device industry benefits from the precision of galvo laser engravers for engraving detailed information on surgical instruments and implants. Additionally, the electronics industry uses these machines for fine-tuning components and creating high-resolution markings on circuit boards.

Comparing Galvo Laser Engravers with Traditional Systems

When comparing a galvo laser engraver to traditional laser systems, the differences in performance become evident. Traditional systems often rely on moving the entire laser head, which can result in slower engraving speeds and reduced accuracy. In contrast, the galvo laser engraver’s use of galvanometer mirrors allows for faster processing times and higher precision. This makes galvo laser engravers particularly suitable for applications requiring intricate and detailed work.

Maintenance and Care for Galvo Laser Engravers

Proper maintenance of a galvo laser engraver is essential to ensure its longevity and optimal performance. Regular cleaning of the mirrors and checking the alignment are crucial tasks to prevent performance issues. Additionally, keeping the laser optics and other components in good condition helps maintain the engraving quality and efficiency of the machine. Regular servicing by a professional can also help address any potential issues before they affect the machine’s operation.

Innovations in Galvo Laser Engraving Technology

Recent advancements in galvo laser engraver technology have led to improved performance and capabilities. Modern galvo laser engravers are equipped with advanced software that enhances control over engraving parameters and designs. Innovations such as higher laser power and more precise mirror control contribute to the expanded range of applications and increased efficiency of these machines. Staying updated with the latest technological developments can help businesses leverage the full potential of galvo laser engravers.

Conclusion

In conclusion, the galvo laser engraver represents a significant advancement in laser engraving technology. Its ability to deliver high-speed, high-precision engraving makes it a valuable tool across various industries. By understanding the workings, advantages, and applications of galvo laser engravers, businesses can make informed decisions and enhance their manufacturing and marking processes. The continued evolution of galvo laser technology promises even greater capabilities and efficiencies in the future.