Hey there! When I first heard about vapour blasting Hamilton, I wasn’t sure how it differed from traditional sandblasting. But once I learned more—and even saw it in action—I realized why it’s quickly becoming one of the most popular restoration methods, especially here in Hamilton. Vapour blasting offers a much gentler, cleaner way to restore and prepare surfaces, and it’s perfect for jobs where precision and care are essential.

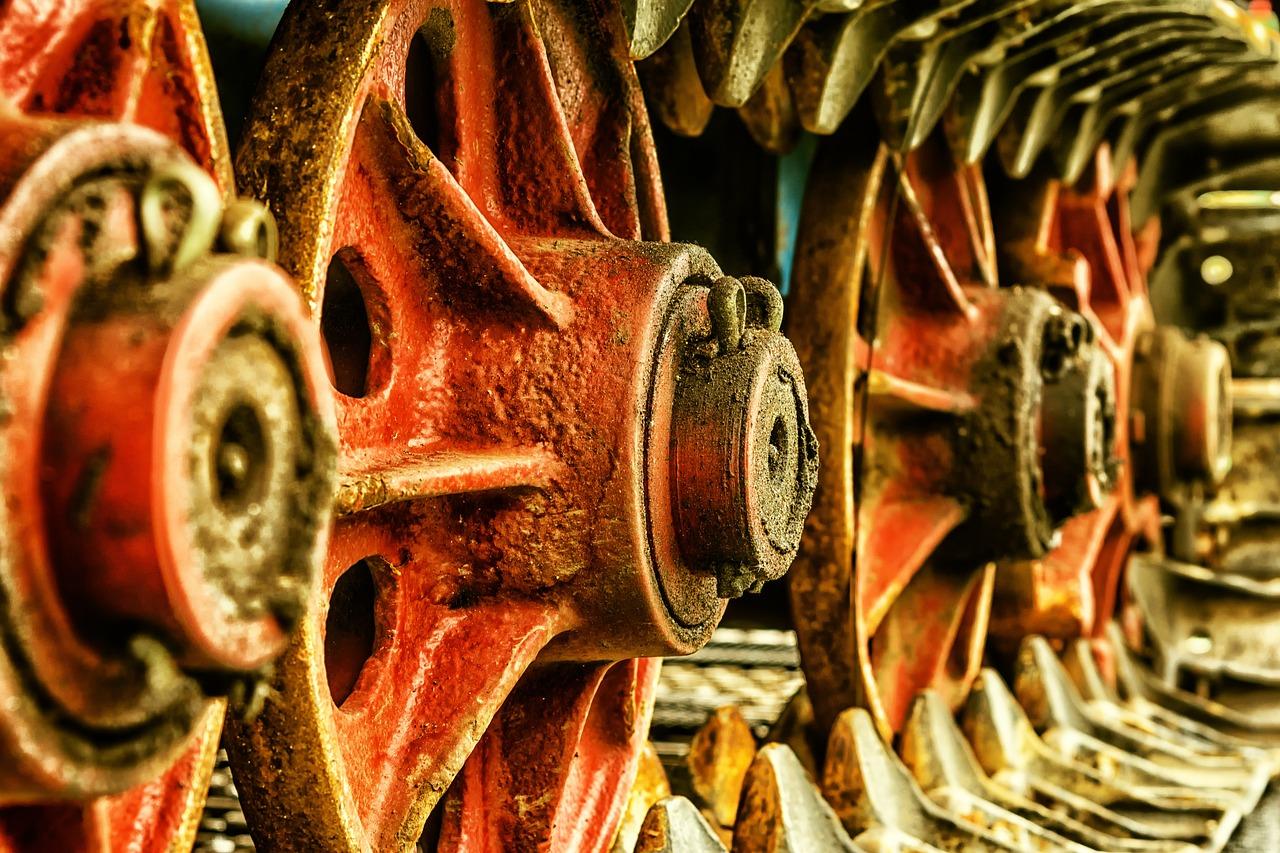

If you’re working on a project that involves delicate materials or intricate parts, vapour blasting might be exactly what you need. Whether you’re restoring a classic car, cleaning up engine parts, or giving old machinery a new life, let me walk you through why vapour blasting in Hamilton is worth considering and why it’s becoming a preferred method for both professionals and hobbyists alike.

What Exactly is Vapour Blasting?

In simple terms, vapour blasting—also known as wet blasting—is a process that combines water with abrasive media to clean and polish surfaces. Unlike traditional sandblasting, which uses dry abrasive materials, vapour blasting mixes the abrasive with water, creating a slurry that’s sprayed onto the surface at high pressure.

What I love about vapour blasting is how gentle it is. The water acts as a cushion, reducing the impact of the abrasive material and preventing surface damage. This makes vapour blasting perfect for more delicate tasks, like cleaning engine parts, aluminum components, or vintage items that require careful handling.

Why Vapour Blasting is a Game-Changer for Restoration Projects in Hamilton

Living in Hamilton, I’ve seen a lot of industries benefit from vapour blasting services—especially in the automotive, industrial, and even marine sectors. Here are some reasons why it’s the go-to option for many local businesses and DIY enthusiasts:

1. Gentle Yet Effective Cleaning

Vapour blasting provides a thorough clean without damaging the underlying material. When I’m working with delicate surfaces, like aluminum or stainless steel, this is a huge advantage. Traditional sandblasting can sometimes leave surfaces pitted or rough, but vapour blasting is much less abrasive, leaving the surface smooth and polished.

For anyone restoring classic cars, motorcycle parts, or vintage machinery, vapour blasting is a godsend. It removes rust, paint, and grime without compromising the integrity of the parts.

2. Versatility Across Different Materials

One of the reasons vapour blasting is so popular in Hamilton is its versatility. I’ve seen it used on everything from engine components and alloy wheels to industrial machinery. Whether you’re dealing with metal, plastic, or rubber parts, vapour blasting can handle it all. It’s even gentle enough to clean delicate items like glass or ceramics!

I’ve personally used it on an old set of motorcycle engine casings, and the results were incredible. They looked brand new, without any of the harsh surface damage that other blasting methods can cause.

3. Superior Finish

Unlike dry blasting, vapour blasting leaves surfaces with a satin-like finish. The water in the process helps to lubricate the abrasive particles, giving the cleaned surface a polished, smooth look. This is particularly important if you’re restoring parts that need to look as good as they perform—like engine casings, alloy wheels, or high-end machinery.

Whenever I’m working on parts that need to be displayed or reassembled in a way that shows off their condition, vapour blasting gives them that pristine, professional finish that’s hard to achieve with other methods.

4. Dust-Free and Cleaner Work Environment

One thing I quickly realized is how much cleaner vapour blasting is compared to other blasting methods. Since it uses water, there’s no dust or airborne particles flying around during the process. This makes it safer and much more pleasant to work with, especially in enclosed spaces.

For businesses in Hamilton that need to keep a clean working environment, this is a huge plus. There’s less mess, less cleanup, and less risk of inhaling harmful dust or debris—something I definitely appreciate when working on restoration projects at home.

5. Great for Intricate or Complex Parts

If you’ve ever tried to clean engine parts or machinery components with tight corners, you’ll know how tricky it can be. Vapour blasting excels in these situations because the water helps carry the abrasive media into all those hard-to-reach spots. It’s perfect for complex parts with intricate details or fine threads.

I’ve used vapour blasting on engine components with tight tolerances, and it not only cleaned the parts beautifully but also left all the intricate details intact—something that’s hard to achieve with more aggressive blasting techniques.

Why Vapour Blasting is Gaining Popularity in Hamilton

Hamilton has a strong industrial and automotive community, and as more people discover the benefits of vapour blasting, its popularity continues to grow. Whether you’re a business owner in the automotive industry or a weekend hobbyist restoring vintage machinery, vapour blasting is becoming a go-to service for anyone needing gentle yet thorough surface cleaning.

I’ve seen local businesses offering vapour blasting in Hamilton for a wide range of projects, from engine part restoration to boat hull cleaning, and the results speak for themselves. The process is quick, efficient, and delivers a finish that’s both functional and aesthetically pleasing.

Choosing the Right Vapour Blasting Service in Hamilton

If you’re thinking about using vapour blasting for your next project, it’s important to choose the right service provider. Here’s what I look for when deciding on a vapour blasting service in Hamilton:

1. Experience and Specialization

Not all vapour blasting services are created equal. Look for a company that has experience working with the specific type of material or parts you need to clean. Whether it’s automotive components, industrial machinery, or delicate vintage items, make sure the service provider has a track record of delivering excellent results.

2. High-Quality Equipment

Vapour blasting requires specialized equipment, and not all blasting setups are the same. Companies that invest in high-quality machines and use the right type of abrasive media will deliver better results. Don’t hesitate to ask about the equipment they use and whether it’s suited to your particular needs.

3. Customer Reviews and Recommendations

Word of mouth is powerful. If you know anyone who has used vapour blasting services in Hamilton, ask them about their experience. Reading reviews or getting recommendations can help you find a reliable provider that consistently delivers top-notch results.

Final Thoughts: Vapour Blasting in Hamilton for Your Restoration Needs

If you’ve got a project that requires surface cleaning or restoration—whether it’s engine parts, metal components, or even delicate items like glassware—I highly recommend looking into vapour blasting services in Hamilton. It’s a gentle, effective method that not only cleans but also leaves your parts looking polished and ready for action.

From personal experience, I can say that the results are incredible, and the process is much cleaner and safer than traditional blasting methods. So whether you’re a hobbyist working on a passion project or a business owner looking to keep your equipment in top condition, vapour blasting Hamilton is definitely worth considering. Once you try it, you’ll see why it’s becoming a go-to method for restoration and cleaning in Hamilton.