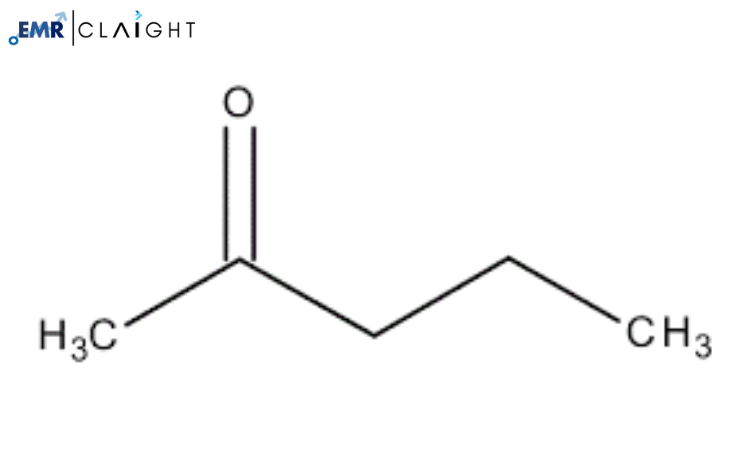

Methyl N-Propyl Ketone (MPK) is a versatile solvent widely used in industrial applications such as coatings, adhesives, printing inks, and chemical synthesis. Known for its excellent solvency, fast evaporation rate, and low density, MPK is a preferred choice in manufacturing and processing industries. With the rising demand for efficient and eco-friendly solvents, establishing an MPK manufacturing plant in 2025 offers a significant business opportunity. This article explores the essential components of setting up an MPK manufacturing plant, from infrastructure and processes to market trends and challenges.

Key Considerations for Setting Up an MPK Manufacturing Plant

-

Site Selection The location of the manufacturing facility plays a critical role in operational success. Key considerations include proximity to raw material suppliers, transportation hubs, availability of utilities like water and electricity, and compliance with environmental and zoning regulations. Setting up the plant near industrial zones can facilitate easier distribution.

-

Raw Material Procurement The production of MPK requires specific chemical precursors, such as propyl alcohol and catalysts. Establishing a reliable supply chain is crucial for maintaining consistent production. Partnering with certified suppliers and creating a stock buffer helps mitigate supply chain disruptions.

-

Facility Design and Layout A well-designed facility optimises workflow and ensures adherence to safety and quality standards. Key sections of the plant include:

- Raw Material Storage: Dedicated areas with controlled environments to preserve material quality.

- Reaction Units: Advanced systems for synthesising MPK through controlled chemical reactions.

- Purification Units: Equipment for distillation and filtration to ensure the product’s purity.

- Quality Control Labs: For rigorous testing of intermediates and final products.

- Packaging and Storage: Facilities to ensure the safe and efficient handling of the finished product.

-

Machinery and Technology The manufacturing process requires specialised machinery for reaction, distillation, and quality control. Automated systems improve efficiency and consistency while reducing manual errors. Regular maintenance of equipment is essential to minimise downtime and maintain operational efficiency.

-

Skilled Workforce A skilled workforce is vital for managing the manufacturing process. Key roles include chemical engineers, technicians, quality assurance experts, and administrative staff. Providing ongoing training on safety protocols, equipment handling, and regulatory compliance ensures smooth operations.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/methyl-n-propyl-ketone-mpk-manufacturing-plant-project-report/requestsample

Manufacturing Process Overview

The production of Methyl N-Propyl Ketone involves several stages, each designed to ensure the purity and efficacy of the final product. Below is an outline of the process:

- Raw Material Preparation: Key ingredients such as propyl alcohol are sourced, tested, and prepared for synthesis.

- Chemical Reaction: The raw materials undergo controlled chemical reactions in reactors, catalysed under specific conditions to form MPK.

- Distillation and Purification: The crude product is purified using distillation and filtration techniques to remove impurities.

- Quality Assurance: The purified MPK is subjected to rigorous quality testing to meet industry standards.

- Packaging: The final product is packaged in secure, industry-compliant containers for storage and transportation.

Regulatory and Compliance Considerations

-

Environmental Compliance Adhering to environmental regulations is crucial for minimising emissions and managing waste effectively. Implementing sustainable practices, such as recycling by-products and reducing energy consumption, aligns with global sustainability goals.

-

Safety Standards Ensuring worker safety involves implementing strict safety protocols, providing protective equipment, and maintaining machinery to minimise risks. Emergency response plans must also be in place.

-

Quality Assurance Compliance with international quality standards such as ISO and GMP enhances product credibility and market acceptance. Robust quality control systems are essential for maintaining consistency.

-

Licensing and Approvals Securing necessary licenses and approvals from local and international authorities is a prerequisite for commencing operations. Regular audits and compliance checks ensure adherence to legal requirements.

Market Trends and Opportunities

-

Growing Demand in Coatings and Adhesives MPK’s excellent solvency and fast evaporation rate make it a key ingredient in high-performance coatings and adhesives. The growth of construction and automotive industries boosts its demand.

-

Applications in Printing Inks MPK is widely used in printing inks due to its ability to enhance drying times and improve print quality. The expansion of the packaging industry further drives its demand.

-

Focus on Eco-Friendly Solvents The increasing emphasis on environmentally friendly products has led to a shift toward solvents like MPK, which offer lower toxicity and reduced environmental impact.

-

Global Expansion Emerging markets in Asia, Latin America, and the Middle East offer significant growth opportunities for MPK manufacturers. Establishing distribution networks in these regions can expand market reach.

-

Technological Advancements Innovations in manufacturing technologies and processes improve product quality and production efficiency. Investing in research and development can open new avenues for MPK applications.

Challenges in MPK Manufacturing

-

Raw Material Price Volatility Fluctuations in the prices of raw materials can impact production costs. Establishing long-term contracts with suppliers and diversifying sourcing strategies can mitigate risks.

-

Regulatory Complexity Navigating stringent regulations for chemical manufacturing requires expertise and resources. Regular updates to processes ensure compliance with evolving standards.

-

Market Competition Competing with established players necessitates innovation, efficient production processes, and effective marketing strategies to capture market share.

-

Energy Consumption The energy-intensive nature of MPK manufacturing requires investment in energy-efficient technologies to reduce operational costs and environmental impact.

Future Prospects

The demand for Methyl N-Propyl Ketone is expected to grow due to its expanding applications in various industries. By leveraging technological advancements, adhering to regulatory standards, and exploring new markets, MPK manufacturers can position themselves as leaders in this dynamic and competitive sector.