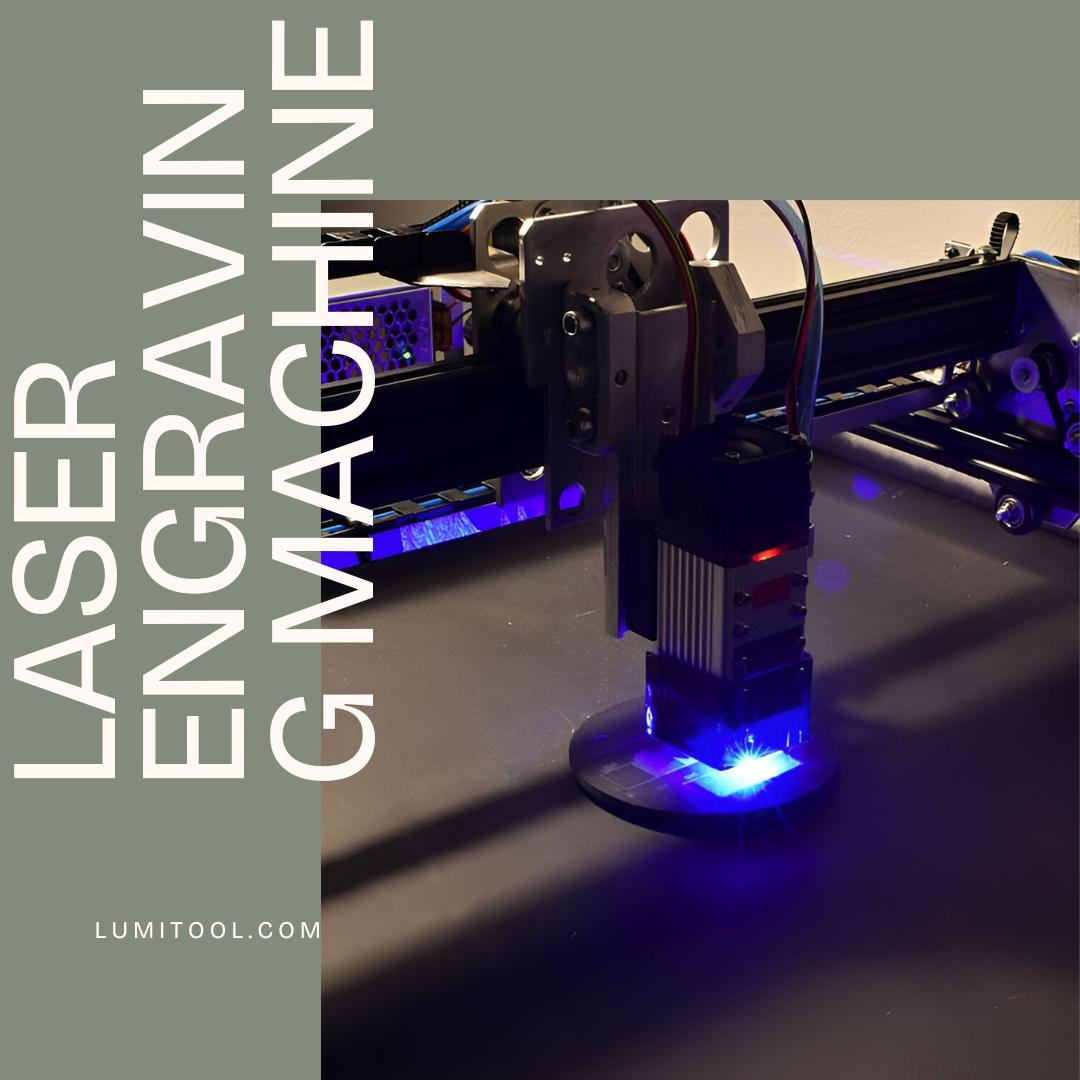

Laser engraving has transformed industrial and commercial marking, offering unparalleled precision, durability, and efficiency. Lumitool Laser Engraver stands at the forefront of this technology, providing cutting-edge solutions for industries requiring high-quality, permanent engravings on a variety of materials. In this article, we explore the features, benefits, and applications of Lumitool’s laser engraving machines and why they are the best choice for businesses.

What is Lumitool Laser Engraver?

Lumitool’s laser engravers are advanced machines that use a high-powered laser beam to etch, engrave, or mark surfaces with extreme precision. Unlike traditional engraving methods, Lumitool’s technology ensures a non-contact, high-speed, and wear-resistant engraving process, making it ideal for industrial applications.

How Does a Lumitool Laser Engraver Work?

Lumitool laser engravers utilize focused laser beams to alter the material’s surface by vaporization, oxidation, or thermal interaction. The process varies depending on the engraving method:

- Deep Laser Engraving: Removes material layers for a tactile, long-lasting mark.

- Surface Laser Etching: Creates high-contrast marks with minimal depth.

- Color Engraving: Alters material properties to produce different colors.

- Micro Engraving: Ideal for small and detailed markings, such as microchips and jewelry.

Key Benefits of Lumitool Laser Engraver

- Ultra-High Precision & Detail – Engraves intricate designs with micron-level accuracy.

- Non-Contact, Damage-Free Process – Works without physical force, preserving material integrity.

- Fast & Efficient Performance – Reduces processing time while maintaining quality.

- Permanent & Wear-Resistant Marks – Resistant to heat, chemicals, and environmental factors.

- Low Maintenance & Cost-Effective – No need for consumables like ink or chemicals.

- Compatible with Various Materials – Works on metals, plastics, wood, glass, ceramics, and more.

Applications of Lumitool Laser Engraving

- Industrial Component Marking – Engraves part numbers, serial codes, and barcodes for traceability.

- Jewelry & Luxury Goods Engraving – Personalizes rings, watches, and other high-end products.

- Electronics & Semiconductor Industry – Engraves microchips, circuit boards, and connectors.

- Automotive & Aerospace Engraving – Marks essential parts for compliance and durability.

- Medical Equipment & Surgical Tools – Creates sterile, permanent markings on instruments.

- Customized Branding & Promotional Items – Engraves logos and designs on corporate gifts and packaging.

Why Choose Lumitool Laser Engraver?

Lumitool’s state-of-the-art laser engraving machines are built for high-performance industrial use, offering:

- Advanced laser technology for high-speed, high-precision engraving.

- User-friendly software for seamless operation and design customization.

- Durable, energy-efficient systems that require minimal maintenance.

- Exceptional customer support to assist with installation, training, and troubleshooting.

Conclusion

A Lumitool Laser Engraver is the ultimate solution for businesses seeking high-precision, permanent, and efficient engraving technology. Whether for industrial applications, branding, or customization, Lumitool’s engravers provide unmatched accuracy, speed, and reliability. Investing in Lumitool’s cutting-edge engraving solutions ensures long-term success and superior product marking.