Acrylic acid stands as one of the most versatile organic compounds in modern industrial chemistry, playing a crucial role in various manufacturing processes and products we use daily. This colorless liquid with its distinctive acrid odor has become an indispensable component in numerous industries, from personal care products to industrial materials.

Chemical Structure and Physical Properties

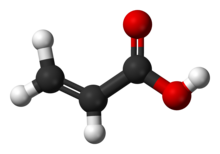

Acrylic acid (CH2=CHCOOH) is the simplest unsaturated carboxylic acid, featuring a vinyl group connected to a carboxylic acid terminus. At room temperature, it appears as a clear, colorless liquid with a characteristic sharp, vinegar-like smell. The compound has a molecular weight of 72.06 g/mol and boils at approximately 141°C. Its unique molecular structure, combining both vinyl and carboxylic acid groups, makes it highly reactive and suitable for various chemical reactions, particularly polymerization.

Manufacturing Process

The production of acrylic acid primarily occurs through the catalytic oxidation of propylene, a process that has been refined over decades of industrial development. The process involves two steps: first, propylene is oxidized to acrolein, and then acrolein is further oxidized to acrylic acid. Modern manufacturing facilities employ sophisticated catalysts and controlled conditions to optimize yield and minimize unwanted by-products. This process has become increasingly efficient, with yields reaching up to 90% in well-optimized systems.

Industrial Applications and Uses

The versatility of acrylic acid makes it an essential raw material in numerous industrial applications. In the polymer industry, it serves as a key monomer for producing polyacrylic acid and its salts, which find extensive use in superabsorbent polymers (SAPs). These SAPs are crucial components in personal care products like diapers and feminine hygiene products.

In the coating industry, acrylic acid derivatives are used to produce acrylic paints, adhesives, and sealants. These products offer excellent durability, weather resistance, and adhesion properties. The textile industry utilizes acrylic acid-based compounds for fabric treatment and finishing, improving properties like water resistance and durability.

Role in Consumer Products

Acrylic acid and its derivatives play a significant role in everyday consumer products. In personal care items, they function as thickeners, dispersants, and rheology modifiers. Products like lotions, creams, and cosmetics often contain acrylic acid-based ingredients to improve their texture and stability.

The compound's derivatives are also crucial in water treatment applications, where they act as scale inhibitors and dispersants. In detergents and cleaning products, acrylic acid-based polymers help prevent soil redeposition and improve the overall cleaning efficiency.

Environmental Impact and Sustainability

The environmental aspects of acrylic acid production and use have gained increasing attention in recent years. While the compound itself is biodegradable, concerns exist about its potential environmental impact during production and processing. Industry leaders have been implementing various measures to reduce emissions and improve production efficiency.

Recent developments include the exploration of bio-based routes for acrylic acid production, using renewable resources instead of petroleum-based feedstocks. These initiatives align with global sustainability goals and respond to growing consumer demand for environmentally friendly products.

Safety Considerations and Handling

Acrylic acid requires careful handling due to its corrosive nature and potential health hazards. The compound can cause severe skin burns and eye damage upon direct contact. Proper personal protective equipment, including chemical-resistant gloves, safety goggles, and appropriate respiratory protection, is essential when handling this material.

Storage requirements include keeping the compound in well-ventilated areas away from heat sources and incompatible materials. Stabilizers are often added to prevent spontaneous polymerization during storage and transportation.

Market Trends and Future Prospects

The global acrylic acid market continues to grow, driven by increasing demand from various end-use industries. The superabsorbent polymer segment remains the largest consumer, particularly in developing regions with growing populations and increasing hygiene awareness.

Technological advancements in production processes and growing applications in emerging sectors like 3D printing and advanced materials are expected to further drive market growth. The industry is also witnessing increased investment in research and development, focusing on improving production efficiency and developing new applications.

Quality Control and Standards

Manufacturing acrylic acid requires strict quality control measures to ensure product consistency and safety. Industry standards specify acceptable levels of impurities, moisture content, and stabilizer concentrations. Regular testing and monitoring are essential parts of the production process, with sophisticated analytical techniques employed to maintain quality parameters.

Get More Insights On Acrylic Acid

Get this Report in Japanese Language

Get this Reports in Korean Language

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)