Are you using a gasketed plate heat exchanger in your industrial process? While these devices are incredibly useful for transferring heat between different fluids, it's important to remember that they can also pose some safety risks. If you want to ensure the well-being of yourself and your employees while working with this equipment, it's crucial to understand what safety considerations you need to keep in mind. In this blog post, we'll explore the ins and outs of gasketed plate heat exchangers, how they work, and most importantly - how to stay safe when handling them. Let's get started!

What are Gasketed Plate Heat Exchangers?

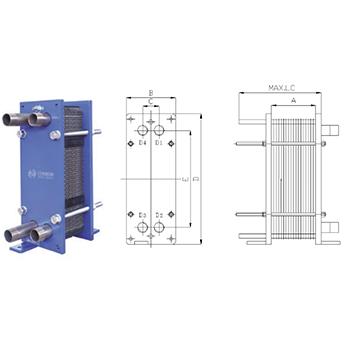

https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B30B.shtmlare devices that are commonly used in industrial processes to transfer heat between two different fluids. These devices typically consist of a series of metal plates, with narrow channels running between them.The fluid that needs to be heated or cooled flows through these channels in one set of plates, while the other fluid (usually water) runs through the alternate set. As the fluids flow past each other, heat is transferred from one to the other until they reach an equilibrium temperature.One key advantage of gasketed plate heat exchangers is their high efficiency - since there is a large surface area in contact between the two fluids, heat can be transferred quickly and effectively. Additionally, because they operate using thin plates rather than bulky tubes or pipes, these devices can take up less space and require less maintenance overall.However, despite their benefits for industrial applications, it's important to remember that working with these machines does come with some safety considerations. In our next section, we'll explore what those are and how you can stay safe when handling gasketed plate heat exchangers in your workplace.

How do Gasketed Plate Heat Exchangers Work?

Gasketed Plate Heat Exchangers are a type of heat exchanger that employ plates and gaskets to transfer heat between two fluids. The process works by allowing the hot fluid to flow through one set of channels while the cold fluid flows through another set of channels, separated by thin metal plates.These plates have small corrugations that help in creating turbulence which enhances the thermal exchange process. As the hot and cold fluids move through their respective channels, they come into contact with each other at every point where the metal plate separates them.The temperature difference causes energy from one fluid to be transferred to the other until both fluids reach an equilibrium temperature.This results in effective heat transfer without any direct contact between the two streams.Moreover, Gasketed Plate Heat Exchangers are highly efficient as they use a large surface area for transferring heat while taking up relatively less space compared to traditional shell-and-tube designs. Their modular design allows them to be easily expanded or reduced depending on demand.Gasketed Plate Heat Exchangers offer an effective solution for various industries such as HVAC systems, food processing plants, chemical processing plants etc., where maintaining high temperatures is necessary but safety is also paramount.

What are the Safety Considerations when Working with Gasketed Plate Heat Exchangers?

When working with gasketed plate heat exchangers, safety should always be a top priority. This equipment operates at high temperatures and pressures, which can pose serious risks if not handled properly.One of the most important safety considerations is to ensure that the heat exchanger is properly installed and secured. Any loose or damaged components can lead to leaks or even accidents.It's also essential to use appropriate personal protective equipment (PPE) when working with gasketed plate heat exchangers. This may include gloves, eye protection, and ear protection depending on the specific job tasks involved.Regular maintenance and inspection are critical for safe operation of this equipment. Checking for leaks, cracks or other damage on a routine basis will help prevent any potential hazards from escalating into major issues.It's crucial to follow all manufacturer guidelines when operating your gasketed plate heat exchanger system. This includes proper handling techniques and adhering strictly to recommended temperature ranges for both heating and cooling applications. By following these best practices, you can ensure a safe work environment while maximizing your efficiency in using this powerful technology.

How to Maintain Your Gasketed Plate Heat Exchanger

Maintaining your gasketed plate heat exchanger is crucial to ensure its longevity and optimal performance. Here are some tips on how to properly maintain your equipment.Regular cleaning of the plates and gaskets is essential in maintaining efficiency and preventing fouling buildup. Use a non-abrasive cleaner with hot water, ensuring all residue has been removed before reassembling.Inspecting the plates for any damage or corrosion is important in preserving their integrity. If necessary, replace damaged plates immediately to prevent further issues.Checking the tightness of bolts holding the frame together should also be done regularly as loose bolts can cause leaks and inefficiency. Tighten them as needed but avoid over-tightening which can lead to warping or cracking of the plates.Regularly checking pressure drops across both sides of the heat exchanger will indicate if there are any blockages that need clearing out. This helps maintain efficient operation while reducing energy costs.It's important to follow manufacturer guidelines when it comes to maintenance schedules such as routine inspection intervals and recommended replacement parts for worn-out components like gaskets or seals.

Conclusion

In today's world, gasketed plate heat exchangers are widely used in various industries. They have proven to be efficient and cost-effective equipment that can effectively transfer heat from one fluid to another. However, it is important to prioritize safety measures when working with these machines.As we have discussed earlier, there are several safety considerations that should not be overlooked while operating a gasketed plate heat exchanger. These precautions include using personal protective equipment such as gloves and eyewear, following proper startup and shutdown procedures, regular maintenance checks, ensuring the right pressure settings among others.By adhering to these guidelines you can ensure both your own safety and the continued safe operation of your gasketed plate heat exchanger for years to come.So if you're planning on using a gasketed plate heat exchanger or already have one in use then make sure you take all necessary steps towards maintaining its upkeep along with observing safety protocols at all times!If you have any need,welcome to contact us![email protected]