The world of industrial processes, from printing and packaging to textiles and nonwovens, hinges on precision and consistency. Advanced tension control algorithms are at the forefront of this transformation, enabling industries to achieve optimal tension levels. The result? Enhanced quality, reduced waste, and heightened operational efficiency. This article dives into the world of advanced tension control algorithms, exploring their definitions, applications, benefits, and the transformative impact they wield across various sectors.

Defining Advanced Tension Control Algorithms

Advanced tension control algorithms represent cutting-edge computational techniques that regulate tension levels in web processing operations. Employing real-time data, complex mathematical models, and feedback loops, these algorithms dynamically adjust tension, ensuring that material speed and tension remain in harmony across a diverse range of web processing scenarios.

Key Principles of Advanced Tension Control Algorithms

Sensor Data Integration

Strategically placed sensors throughout the web production line provide real-time inputs, including tension, speed, diameter, and temperature. These data points serve as the foundation for algorithmic analysis.

Mathematical Models

Advanced tension control algorithms harness intricate mathematical models based on sensor data. These models predict tension fluctuations, taking into account material properties, processing variables, and historical data for accurate forecasts.

Feedback Loops

A central tenet of these algorithms is continuous feedback loops. By comparing anticipated tension levels with actual measurements, the algorithms make real-time adjustments to the tensioning systems, ensuring that the desired tension is maintained.

Adaptive Control

In contrast to traditional methods, advanced algorithms adapt in real time to changing conditions. Swiftly responding to disturbances like speed fluctuations, material attributes, and abrupt starts and stops, they ensure consistent tension levels.

Applications in Various Industries

Flexible Packaging

Advanced tension control algorithms ensure precise tension levels in flexible packaging processes, enhancing quality and reducing material wastage during printing, laminating, and slitting operations.

Printing and Coating

In high-speed printing and coating, these algorithms deliver impeccable image registration and coating application by compensating for speed, temperature, and substrate changes.

Textiles and Nonwovens

Indispensable in textile weaving, knitting, and nonwoven production, advanced tension management yields uniform fabric creation, diminished distortions, and optimized material utilization.

Converting Machinery

Converting machines such as rewinders, sheeters, and slitters benefit from these algorithms' stable tension control, which adapts to roll diameter, speed, and material attributes, minimizing faults and downtime.

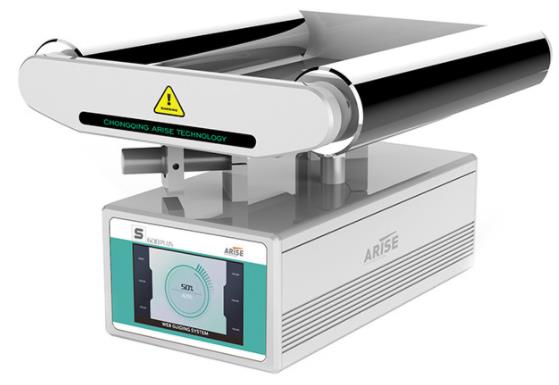

Automated Web Guiding Systems

Teaming up with web guide systems, advanced tension control algorithms achieve both alignment and tension management simultaneously, offering a comprehensive approach to web processing.

Advantages of Advanced Tension Control Algorithms

Precision

Exceptional precision is maintained even in complex processing scenarios, ensuring consistent tension levels.

Quality Enhancement

Flaws and irregularities are minimized by eliminating tension variations, resulting in higher-quality end products.

Material Efficiency

Optimized tension control system reduces material wastage, contributing to sustainability efforts and cost savings.

Operational Efficiency

Automation and predictive capabilities reduce manual intervention, enhancing overall process efficiency and minimizing downtime.

Flexibility

The flexibility of advanced algorithms suits a wide range of processing conditions and materials, making them versatile for various industries and applications.

Reduced Maintenance

Stable tension levels reduce wear and tear on machinery and components, extending equipment lifespan.

The Future of Advanced Tension Control Algorithms

As technology progresses, enhanced tension control algorithms will reach new heights:

Integration with Industry 4.0

Integration with artificial intelligence (AI) and machine learning will empower algorithms to learn from historical data, respond to intricate processing scenarios, and accurately predict tension fluctuations.

Predictive Maintenance

Advanced algorithms will introduce predictive maintenance strategies, identifying potential issues before they lead to equipment breakdowns by continuously analyzing sensor data.

Real-time Optimization

These algorithms will dynamically optimize tension by processing large data volumes in real time, responding to changing conditions and ensuring consistent quality.

Human-Machine Collaboration

The future lies in human-algorithm collaboration. Operators will work alongside algorithms to fine-tune settings, interpret data insights, and make informed decisions, resulting in higher product quality and operational efficiency.

Conclusion

Advanced tension control algorithms are the driving force behind transformative changes in various industries, redefining product manufacturing and enhancing quality, efficiency, and sustainability. Their role in establishing precision and consistency in web processing applications is set to shape the future of multiple sectors as technology continues to advance.