In assessment to everyday alloys, an aircraft grade aluminum sheet has higher performances in strength, sturdiness, fatigue resistance and plasticity. Unique kinds and grades are as underneath.

1. Duralumin: aluminum magnesium copper alloy. The most extensively used aluminum alloy in the aviation enterprise. 2024, 2A12 and 2017A are usually used, with good energy, sturdiness, fatigue resistance and plasticity. It's miles used to make plane skins, partition frames, wing ribs, etc.

2. Remarkable difficult aluminum: aluminum zinc magnesium copper alloy. 7075 and 7A09 are generally used. They have high electricity limit and yield energy, and endure massive load. They're used to manufacture the top wing pores and skin, girder, etc.

3. Antirust aluminum alloy: usually used aluminum magnesium alloy 5A02, 5A06, 5B05. It has excessive corrosion resistance, fatigue resistance, suitable plasticity and weldability. Used to make mailbox, oil pipe, and so on.

Four. Cast aluminum alloy, usually used 6A02, has high hardness and exact corrosion resistance. Make engine parts, joints, etc.

5. Casting aluminum alloy, small precise gravity, excessive corrosion resistance and heat resistance, manufacturing engine case, and many others.

The overpowering benefit of an aircraft aluminium plate is its splendid mechanical homes. Take 7075 aluminium sheet for example. It ranks top in hardness amongst all aluminum alloys. In contrast, other alloys like 5052, 3003 and 1100 have a miles lower hardness, appropriate simplest for simple commercial production. Of path, the rate of plane aluminium alloy proves to be higher, too.

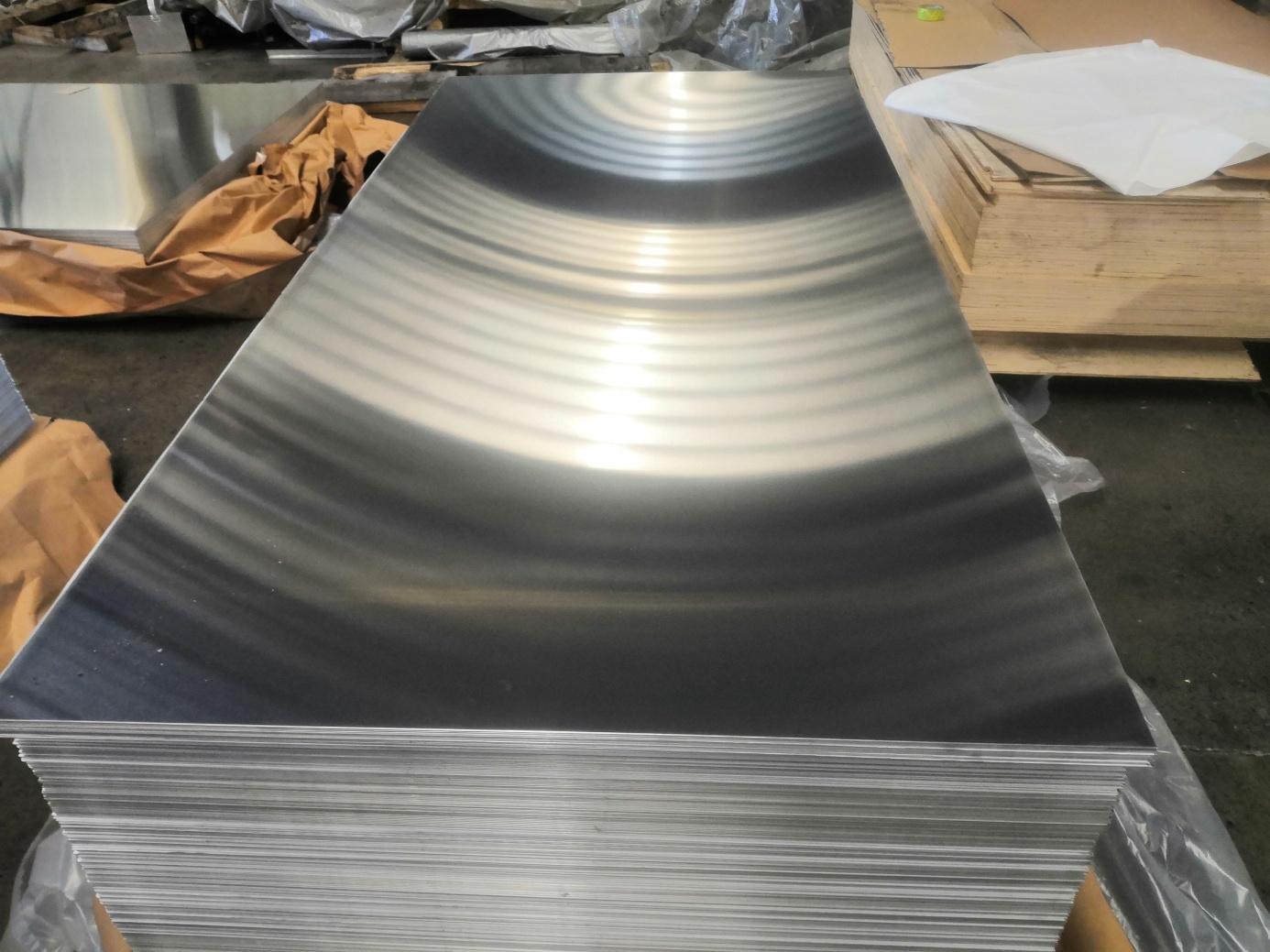

Plane aluminum sheet metal alloys and grades