1060 aluminum circle for cooking utensils may be of temper O, H12 or H14. Thickness levels from zero.36mm to 5mm, and diameter from 120mm to 1000mm. The floor of the circle is normally mill completed, even though shade coating and anodizing may be custom designed consistent with per client’s sensible needs. Mill finish 1060 aluminium circle are for ordinary cooking utensils made via processing steps of grinding, sandblasting and squeeze the lid. A pot comes into being in this way. Covered and anodized circles are processed into higher give up cookware, inclusive of strain cookers, pizza baking pans, non-stick pan cake cookers and so on.

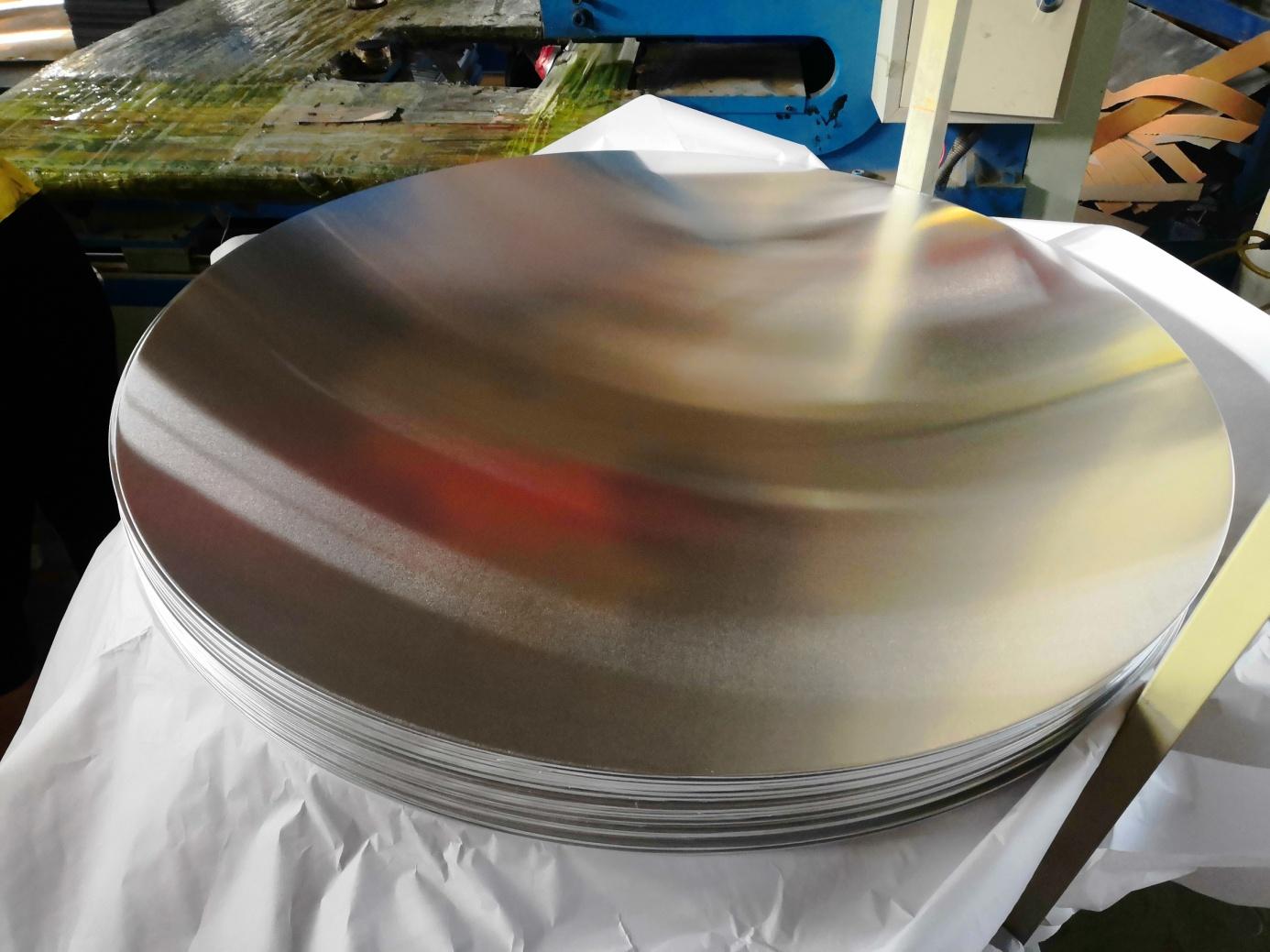

The specs of our 1060 aluminum circles are entire. In addition to the conventional size, the disk with the thinnest zero.2 mm and the thickest thickness of 6.5 mm can be provided. The surface overall performance of the circle is so proper that no apparent scratches, oil stains, oxidation or black spots seems at the floor. When the thickness of the circle is >zero.5 mm, we are able to make certain that the rims of the finished product are neat and burr-free. We maintain proper manipulate of the grain size grade and elongation of the coil within the early stage, ensuring the extremely good deep drawing and spinning performance of the circle, successfully fending off the possibility of post processing.

1060 aluminum circle, containing ninety nine.6% aluminum composition, is also referred to as a pure aluminum disc. It has exact elongation and tensile energy, assembly traditional processing necessities (stamping, stretching and so on.) with excessive formability. It's also used as industrial aluminum sheet with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.1060 circle can withstand a spread of strain processing and extension, bending. Owing to the fact that its charge is lower than different grade alloy. 1060 aluminum circle for utensils is widely utilized in cookware, light enterprise and traffic signs and symptoms,and so on.

1060 aluminum circle for cooking utensils