When it comes to projects in which the total amount of weight is a concern, it is customarily recommended to make use of materials that are lighter in weight. Despite the fact that they are not as heavy as other materials, they are still exceptionally long-lasting and have the ability to withstand a significant amount of pressure without cracking or breaking. This is because they have the ability to withstand a significant amount of pressure without breaking or cracking. Unfortunately, they do not provide a very good value for the money because, in the vast majority of cases, they do not include all of the necessary material features that are desired for the project. This is because they do not include all of the features that are desired for the project. These characteristics are necessary for the accomplishment of the goal in order to be successful.

You have the option of using materials that are heavy or materials that are lightweight; this is one of the reasons why it is important to prioritize the most important characteristics for your CNC-machined component in order to get the best results. Another reason why it is important to prioritize the most important characteristics is that you have the option of using materials that are heavy or materials that are lightweight. You will be able to determine the aspects of your component that must be present for it to function correctly in this manner, and you will be able to do so. After that, you will be able to eliminate the materials that do not satisfy those standards and then evaluate the prices of the materials that are still in the running for the position.

It is not the only factor that can determine an object's strength; rather, what is taken into consideration is an object's capacity to resist a particular amount of weight. There are additional facets that might also call for some research to be done, such as the following ones:

Tensile strength is the resistance of an object to breaking when it is subjected to tension. Tensile force is the force that causes an object to stretch or pull. PSI is a unit of measurement that can be used to express this level of resistance.

The ability of an object to withstand friction or to lubricate itself on its own accord is what's referred to as that object's wear resistance. Another term that can be used to describe this capacity is self-lubrication. Citation needed. It is a product that performs functions that are analogous to those of Teflon®, but its abrasion resistance is significantly higher than that of Teflon®.

The ability of something to withstand pinpoint surface loads that are applied in a uniform manner is how hardness is defined. Case in point: Case in point: Case in pointTake, for example:Take, for example:For example,It is common practice to use a number that describes the material as having a Brinell or Rockwell hardness in order to indicate the level of hardness possessed by the material in question. This can be done in order to indicate the level of hardness possessed by the material.

How much do you think the project will end up costing in its entirety once everything has been said and done?

In general, the materials that have a high strength rating while also being relatively light in weight are the ones that command the highest prices. This is because of the combination of these two characteristics. This is not only the method that will help you save the most money overall, but it is also the method that will help you choose a component that is both efficient and cost-effective in the best possible way. This is due to the fact that doing so will make it easier for you to zero in on the things that are most important to you.

If you want to start saving money as soon as possible, you should look for a company that will provide you with free estimates and does not require a minimum purchase for their products. This is one way in which you can immediately cut down on your expenses. You will be able to achieve this objective once you have zeroed in on the specifics and gained a better understanding of them.

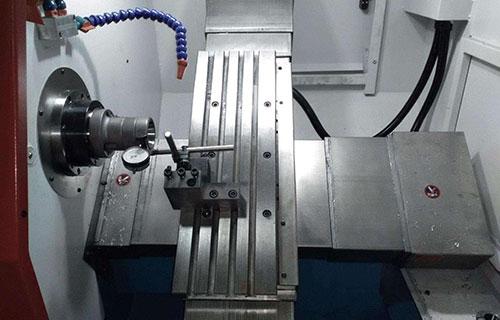

It's possible that the question you're thinking of right now isn't the most appropriate one to ask, and that a question about the different kinds of materials that can't be used would be a better one to ask instead. Sawing through virtually any material that one could possibly think of is within the capabilities of CNC machines. Despite the fact that a CNC milling services machine can work with a very wide range of different materials, the following materials are the ones that are utilized in a CNC machine the majority of the time: metals, plastics, and ceramics.

There is a wide variety of metals, the most common of which are steel, aluminum, brass, and brass. There are also other types of metals.

Plastics are composed of a wide variety of constituent parts, the most common of which are polycarbonate (PC), polypropylene (PP), acetal (POM), and acrylics (PMMA). Polycarbonate is the most common of these four.

The term "foam" can refer to either carving foam or rigid foam; the latter two types of foam are typically lighter but have a longer lifespan than the former type of foam does.

Which Kind of Material Ought to Come First in Your Attempts to Make Use of It?

There is a good chance that you will be able to zero in on the kind of material that will serve your component in the most effective manner if you give each of the aforementioned considerations the full attention that they deserve. This is because you will be able to pinpoint the kind of material that will serve your component in the most effective manner. Because of this, you will be able to zero in on the type of material that will give your component the highest possible level of service. CNC Machining Aluminum is possible that in order to find the best configuration, it will be necessary to carry out some trial and error and experiment with a wide range of different options. This is one of the many possibilities. Rigid foam, which can be found in a variety of densities, is the most effective insulating material. It can function normally in environments with temperatures ranging from -100 degrees Fahrenheit to 200 degrees Fahrenheit, which enables it to carry out the task for which it was primarily intended. This is because rigid foam has a higher R-value than other types of foam, which enables it to perform exceptionally well as an insulator. Another reason for this is that rigid foam is more durable than other types of foam.

Carving foam is a specialized form of foam that can be sculpted into virtually any form that one's imagination can conjure up. Carving foam is available in a wide variety of colors and patterns. A component that has a high density and is able to withstand temperatures that are very high is called polyisocyanurate, and it is a substance known as polyisocyanurate. This component is present in carving foam, as it is part of the carving foam and can be found there.

Phenolics: If you are required to meet military-grade specifications like MIL-I-24768, for example, one way to fulfill this requirement is to make use of phenolics. Using phenolics is one way to fulfill this requirement. There is a wide selection of options to pick from, and some of the choices that are available include CE, LE, G10, G10/FR4, G9, G11, and G7. Each one possesses a unique set of advantages. If we take CE material as an example, the fine weave of phenolic linen results in good mechanical properties, dimensional stability, and a better finish for machined components. These benefits can be attributed to the use of CE material. These advantages are directly attributable to the utilization of CE material. These benefits can be attributed, in no uncertain terms, to the utilization of CE material. The requirements of the Mil-I-24768/13 FBE specification can be met by LE phenolics, whereas the requirements of the Mil-I-24768/14 FBG specification can be met by CE phenolics. Either of the two sets of phenolics can fulfill the requirements of Mil-I-24768 successfully.

Plastics: Plastics come in a wide variety, the vast majority of which are put to use as bushings, bearings, or for the purpose of providing electrical insulation. Plastics can also be used for a variety of other purposes. In addition, a wide variety of other applications are possible for plastics. Plastics also have a wide range of other applications that can be pursued, which is quite impressive. Having said that, there is a demand for the many different kinds of plastics that are utilized in applications that are of a more general nature.