Carbon DLS (digital light synthesis) is an industrial 3D printing process that creates functional, end-use parts with mechanically isotropic properties and smooth surface finishes. You can choose from both rigid and flexible polyurethane materials to meet your application needs for high impact-resistance components.

Common application for Carbon DLS are:

complex designs that are challenging to mold

need for isotropic mechanical properties and smooth surface finish

production parts in materials comparable to ABS or polycarbonate

durable components for end use

Carbon DLS Material Options

RPU 70 Rigid Polyurethane is manufactured through Carbon’s DLS (digital light synthesis) process. It is a tough all-purpose engineering grade material that comes in black and can be categorized as an ABS-like materials. Ideal part sizes for Carbon materials are 5 in. x 5 in. x 5 in. or less.

Primary Benefits

Tough material

UL 94 HB flame resistance classification

Carbon FPU 50 exhibits the highest elongation of any of the 3D printing thermoset resins at 200% making it the most flexible option. Available in black, it falls under the PP-like category of 3D printing resins.

Primary Benefits

Highest elongation properties

Fatigue resistance

The Carbon DLS™ Process

DIGITAL LIGHT PROJECTION: UV LIGHT SHAPES THE PART

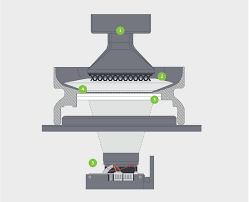

The Digital Light Synthesis process is driven by Carbon’s groundbreaking Continuous Liquid Interface Production™, or CLIP™. CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies and the build platform rises.