When oil is extracted from a well, the well will typically produce other byproducts as well, including a certain amount of natural gas, water, and solid particles in addition to the oil itself. These byproducts are known as "byproducts of extraction."This is done to ensure that there will be no air leaks during the transportation of the oil and gas. Other benefits include lowering the back pressure at the wellhead, increasing the crude oil production, improving the development benefit, and successfully achieving the objective of transporting oil and gas in an airtight manner. During the design phase of the mixed-transport system, both the properties of the mixed-transport medium and the mixed-transport pump with a single screw are subjected to an in-depth analysis. This contributes to ensuring that the system will operate as it was designed to. In the context of the procedure, this particular point of contact is referred to as the sealing line.

Because of this, the cavity that is contained within the stator moves axially as a consequence, which ultimately results in volume displacement. The media has to be moved from one end to the other in order to complete the task. This is due to the fact that the stator is constructed out of a rubber-like material that has a high degree of elasticity. When the pump is operating, the sealing line is able to effectively prevent gas from passing nitrile stator through it, which enables the pump to fulfill its purpose of conveying gas; when the medium contains solid particles, if the solid particles are squeezed into the sealing line, the rubber surface of the stator is compressed due to the elastic action of the rubber stator, and the solid particles are conveyed through the pump; when the medium does not contain solid particles, the sealing line is able to effectively prevent gas from passing through it; this When there are no solid particles present in the medium, the sealing line is in a better position to successfully block the passage of gas through it.

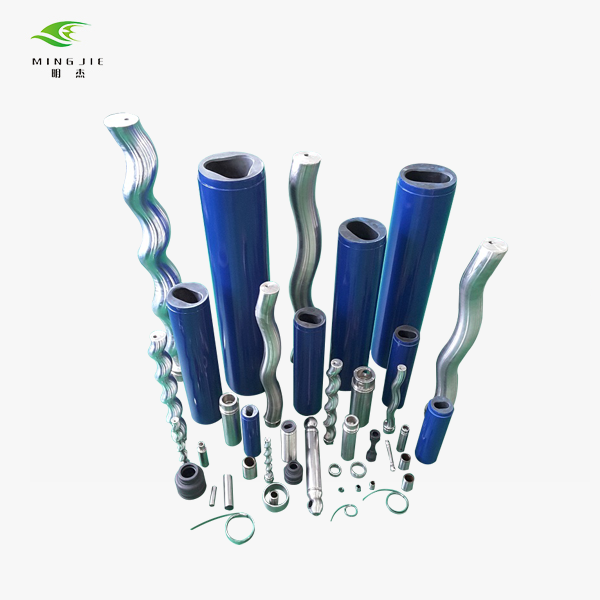

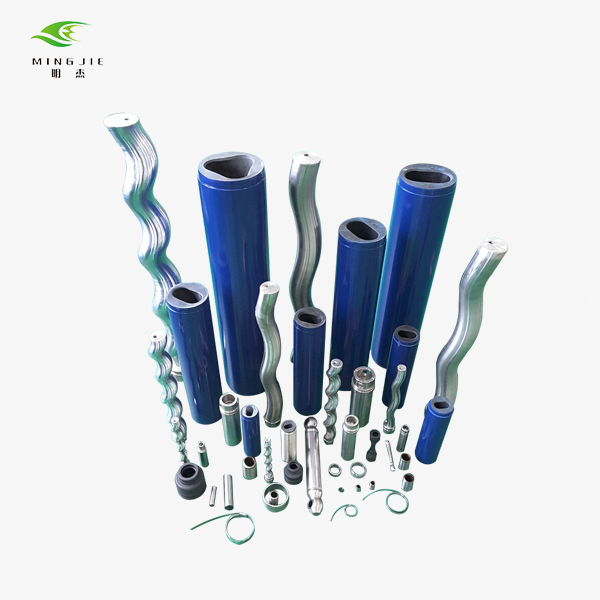

It is possible to transport corrosive media, media that contains gas, media that contains sediment-containing solid particles, and media that has a high viscosity with the assistance of a single-screw oil and gas mixing pump. All of these types of media can be mixed together in a single pump.5 and 32 millimeters, the flow rate is proportional to the rotation speed, and the pressure can be maintained even with a low flow rate and a slow rotation speed. Despite the fact that the flow rate is proportional to the rotation speed, the pressure can be maintained even with these conditions. Because of the capabilities of this technology, automatic control can be easily implemented and possesses excellent adjustment performance. This is all thanks to the capabilities of this technology. One more factor that is very similar to the others is the amount of solid content. This is the case because the gaseous equation describes how the state of the gas changes when it is subjected to different pressures and temperatures. As a result, the gaseous equation accounts for this phenomenon. In addition, the pressure will have an effect, which will vary depending on the circumstances, on the total amount of gas that is dissolved in the liquid.

Liquid Feed Rate

The term "liquid feed rate" refers to the proportion of the liquid phase composition to the flow rate that occurs when the medium is introduced to the pump. This ratio occurs when the liquid phase is introduced. The rate at which liquid is added to a system is referred to as the liquid feed rate. This term is used to refer to the volume ratio in a sense that is a little bit more specific. With the idea of liquid feed rate progressive cavity pump food grade, the liquid feed rate reflects the operation of the pump regardless of the oil-gas ratio, the amount of moisture that is present in the liquid, the amount to which the gas is compressed, and the amount of solid particles that are present in the medium. This is because the concept of liquid feed rate is based on the idea that the amount of solid particles that are present in the medium is directly proportional to the amount of liquid feed rate.

It has been determined, through the preliminary analysis of test and oilfield operation data, that the single-screw pump is able to function normally if the liquid inlet rate is not lower than 5%. This finding was made possible by the fact that the liquid inlet rate was kept constant throughout the testing process. It is possible for 5% of the liquid to remove the frictional heat that is produced by the relative movement of the rotor and the stator, and it is also possible for 5% of the liquid to lubricate the meshing surface of the rotor and the stator so that the screw pump can continue to function normally. Both of these effects are possible when 5% of the liquid is used. When only five percent of the liquid is used, either of these effects could occur. For instance, the percentage of gas present may be relatively high during a certain time period, whereas the percentage of liquid present may be relatively high during a different time period. Because of this, when transporting a mixture of oil and gas using a single screw pump, special precautions need to be taken to ensure that the pump does not move either liquid or gas. These precautions need to be taken to prevent the pump from moving either liquid or gas. This, in turn, has the effect of speeding up the process by which the rubber ages, which, in turn, has the effect of reducing the stator's useful life.