According to different manufacturing processes, Marine Grade Aluminum Sheet for shipbuilding can be divided into deformed aluminum sheets and cast aluminum sheets. Since marine aluminum sheets have special requirements for strength, corrosion resistance and weldability, aluminum-magnesium alloys, aluminum-magnesium-silicon alloys and aluminum-zinc-magnesium alloys are mostly used in shipbuilding marine aluminum sheets. Among them, 5000 series aluminum-magnesium alloys are the most widely used on ships. So, what are the characteristics of the 5000 series marine shipbuilding aluminum plate?

Marine 5000 series aluminum plates mainly include 5083, 5086 and 5456 aluminum plates. 6000 series aluminum alloys are widely used in the superstructure of ships because intergranular corrosion occurs when used in seawater. The disadvantage of 7000 series aluminum alloy is poor corrosion resistance, so the application range is limited. In general, the 5000 series marine aluminum sheet is the most widely used and most promising aluminum sheet product. 5083 aluminum plate can be regarded as the representative product of 5000 series marine aluminum plate, and the status is O, h111, h112, h116, H321, etc. The alloy composition of 5083 aluminum plate is silicon Si: ≤ 0.40, copper Cu: ≤ 0.10, magnesium mg: 4.0-4.9, zinc Zn: ≤ 0.25, manganese Mn: 0.40-1.0, titanium Ti: ≤ 0.15, chromium Cr: 0.05-0.25 , Iron Fe: 0-0.400. 5083 aluminum plate has medium strength, good corrosion resistance and formability, and high degree of corrosion fatigue resistance, generally used as the main structure of the hull. Others, such as 5052, 5086, 5454, 5456, etc. Also commonly used in hull structures or pressure vessels, piping, hulls and decks.

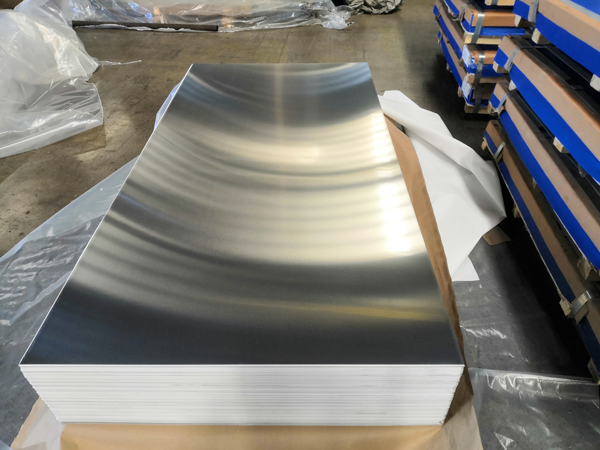

Generally speaking, the thickness of aluminum used in shipbuilding is determined by the hull structure, the size of the ship and the parts used. Generally, from the perspective of light weight of the hull, try to use the thin aluminum plate as much as possible, but also consider the corrosion depth of the aluminum plate for shipbuilding during the service time. The commonly used aluminum plates are thin plates above 1.6mm and thick plates above 30mm. There are also special specification sheets that are used under shipyard contracts.

5000 series marine aluminum for shipbuilding | Huawei