The primary differences between powder coating and other finishing techniques such as anodizing and electroplating are their processes, properties, and suitability for various applications. Here's the breakdown:

Process

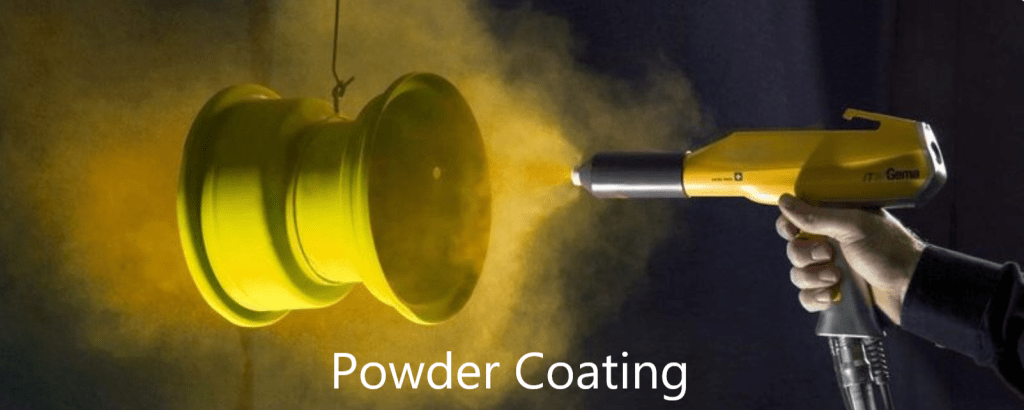

- Powder coating:A dry powder is electrostatically applied to the object's surface and baked to cure, resulting in a hard, durable layer.

- Anodizing: An electrochemical process that thickens the naturally occurring oxide layer on the surface of certain metals, primarily aluminum.

- Electroplating: A metal coating is deposited onto another metal using an electric current to form a new metallic layer.

Properties

- Durability:All three provide excellent durability, but powder coating is the most resistant to scratches, chips, and corrosion. Anodizing also has excellent corrosion resistance, whereas electroplating's durability is dependent on the metal used.

- Thickness:Powder coating typically results in the thickest layer, followed by anodizing and electroplating. This can have an impact on weight and the ability to hide surface imperfections.

- Appearance: Powder coating provides a wide range of colors and textures, whereas anodizing creates metallic finishes. Electroplating only affects the appearance of the deposited metal.

- Conductivity: Anodizing and electroplating can maintain or improve the conductivity of the base metal, while powder coating acts as an insulator.

Suitability

- Powder coating:Ideal for general-purpose applications that require durability, affordability, and a variety of color options. It's ideal for hiding surface flaws, outdoor items, and a variety of materials such as metal, wood, and plastic.

- Anodizing:Ideal for aluminum parts that require lightweight, corrosion-resistant finishes, particularly in applications requiring conductivity or a specific metallic look.

- Electroplating:Suitable for adding specific metal finishes, improving corrosion resistance, and increasing conductivity in various applications. However, it may be more expensive and raise environmental concerns.

Additional factors

- Material compatibility: Anodizing is limited to specific metals, whereas powder coating can be applied to a variety of materials. Electroplating can be used on a wide range of metals, but compatibility must be carefully considered.

- Cost: Powder coating is the most affordable option, followed by anodizing and electroplating, which can be costly for complex finishes.

Finally, the best technique for your project is determined by its specific requirements, budget, and desired characteristics. Consider material, durability, appearance, conductivity, and cost when deciding which option is best for your application.