In the world of electronics manufacturing, precision and efficiency are paramount. The advent of multi-angle automatic placement machines has revolutionized the process of printed circuit board (PCB) assembly. These advanced machines offer a range of benefits, including increased productivity, improved accuracy, and reduced human error. In this blog post, we will explore the ins and outs of using multi-angle automatic placement machines, providing a comprehensive guide for both beginners and experienced professionals. From understanding the basic principles to optimizing machine settings, Lieqi will delve into the key aspects of harnessing the full potential of these cutting-edge devices.

1. Understanding Multi-Angle Automatic Placement Machines

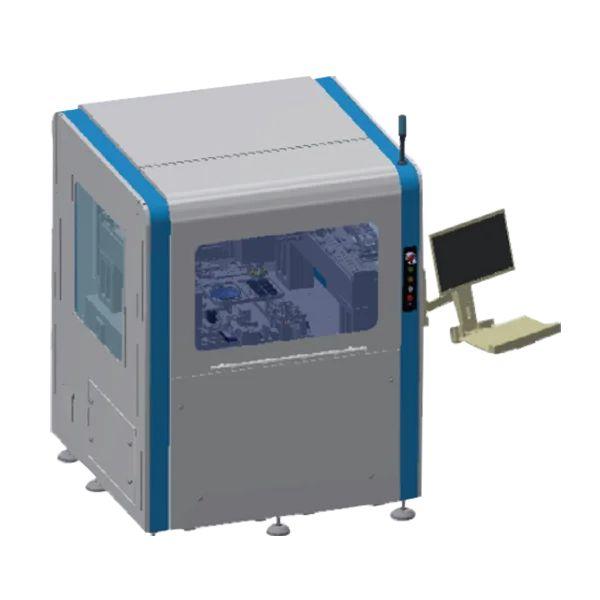

To effectively utilize multi-angle automatic placement machines, it is crucial to grasp their fundamental workings. These machines employ robotic arms equipped with high-precision nozzles to pick and place electronic components onto PCBs. Unlike traditional single-angle machines, multi-angle machines offer the ability to rotate the PCB and components at various angles, enabling greater flexibility and accuracy during assembly. By understanding the machine's components, such as the vision system, feeders, and placement heads, users can make informed decisions and optimize their workflow.

2. Preparing for Multi-Angle Assembly

Before diving into the assembly process, proper preparation is essential. This includes ensuring the PCB design is compatible with multi-angle assembly, optimizing component libraries, and verifying the accuracy of the component placement data. Additionally, users must consider factors such as component orientation, rotation limits, and clearance requirements. By meticulously preparing the PCB layout and associated data, users can minimize errors and maximize the efficiency of the multi-angle automatic placement machine.

3. Setting Up the Machine

Proper machine setup is crucial for achieving optimal results. This involves calibrating the machine's vision system, adjusting placement head parameters, and fine-tuning nozzle settings. Additionally, users must configure the machine's software to match the specific requirements of the PCB assembly project. By following manufacturer guidelines and leveraging advanced machine features, users can ensure precise component placement and minimize the risk of defects or misalignments.

4. Programming and Optimization

Programming the multi-angle automatic placement machine is a critical step in the assembly process. Users must create or import the component placement data, define the assembly sequence, and specify any rotation or angle adjustments required. Additionally, optimizing the programming parameters, such as pick-and-place speed, nozzle pressure, and vision system accuracy, can significantly impact the overall efficiency and quality of the assembly. Through iterative testing and fine-tuning, users can achieve the desired results and streamline the production process.

5. Troubleshooting and Maintenance

Even with careful preparation and setup, issues may arise during multi-angle assembly. Understanding common challenges, such as component misalignment, nozzle clogging, or vision system errors, is crucial for efficient troubleshooting. Regular machine maintenance, including cleaning, calibration, and component inspection, is also essential to ensure consistent performance and prolong the machine's lifespan. By promptly addressing issues and adhering to maintenance schedules, users can minimize downtime and maximize the machine's productivity.

Conclusion

Multi-angle automatic placement machines have revolutionized PCB assembly, offering increased efficiency, precision, and flexibility. By understanding the fundamental principles, preparing meticulously, setting up the machine correctly, programming and optimizing the assembly process, and troubleshooting effectively, users can harness the full potential of these advanced devices. As technology continues to evolve, it is crucial for electronics manufacturers to stay updated with the latest advancements in PCB assembly equipment. By embracing multi-angle automatic placement machines and implementing best practices, manufacturers can enhance their productivity, reduce costs, and deliver high-quality products to meet the demands of the ever-evolving electronics industry.

https://www.szlieqi.com/How-to-use-multi-angle-automatic-placement-machine.html