Over the years, the printing industry has witnessed significant advancements, with technology playing a crucial role in transforming printing processes. One such technological breakthrough that has gained tremendous traction is the web guiding system. Web guiding systems have become a vital tool for the printing industry, offering improved precision, higher production efficiency, cost savings, flexibility, quality assurance, connectivity with digitalization, and a wide range of applications.

What is a Web Guiding System?

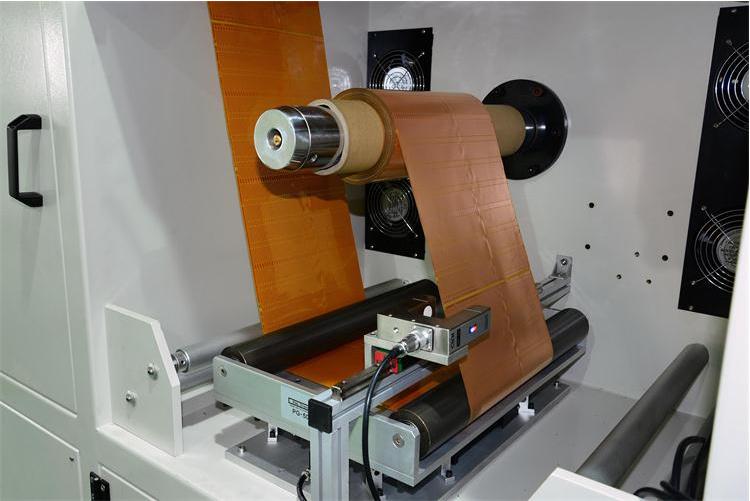

A web guiding system, also known as a web guiding control system or web alignment system, is a technology used in various industries, including printing, packaging, and paper manufacturing. These systems are designed to accurately control the position and alignment of a moving web of material during the manufacturing process. A web refers to a continuous sheet of material, such as paper, film, or fabric, that is unwound from a roll and subjected to various treatments or printing processes.

Web guiding systems can be implemented in different ways, depending on the specific requirements of the manufacturing process. They utilize edge guide sensors, line sensors, or vision systems to determine the position of the web. Actuators, such as mechanical guides, steering rollers, or motorized actuators, are then used to adjust the web's position based on the sensor feedback.

Why are Web Guiding Systems Important in the Printing Industry?

Enhanced Precision and Accuracy: Web guiding systems address alignment issues during the printing process. They ensure precise color and image registration, minimizing waste and enhancing print quality. These systems enable printers to consistently produce aligned and high-quality prints, even at high speeds, by accurately guiding the web through the printing machine.

Increased Production Efficiency: Downtime and setup time can significantly impact productivity in the printing industry. Web guiding systems reduce these interruptions by quickly correcting any web alignment changes. This allows for faster printing speeds, fewer manual interventions, and uninterrupted operation, leading to increased production efficiency.

Cost Savings: Web guiding systems offer substantial cost savings in an industry where material waste and rejections can greatly impact profitability. These technologies enhance operational efficiency by reducing misprints, minimizing material waste, and maximizing resource utilization. Additionally, the prompt detection and correction of web misalignments help save costly rework and reprinting expenses. Furthermore, the reduced maintenance and repair requirements of printing equipment contribute to cost savings.

Flexibility and Adaptability: The printing industry encompasses various substrates, printing techniques, and formats. Web guiding systems effectively handle these complexities. They accommodate different web widths, adapt to diverse formats, and facilitate quick changeovers regardless of the substrate type or printing method used. Their flexibility and adaptability enable printers to efficiently meet evolving customer demands.

Quality Assurance: Consistency and quality are paramount in the printing business. Web guiding systems play a critical role in ensuring print consistency and repeatability. These technologies eliminate flaws such as creases, misalignments, and print irregularities, ensuring that every printed product meets the highest standards. As a result, customer satisfaction increases, and printing companies enhance their reputation.

Integration with Digitalization: As the printing industry embraces digitalization, web guiding systems seamlessly integrate with digital workflow systems. They provide real-time monitoring and control, allowing operators to make changes on the fly. This integration improves overall operational efficiency and productivity by enabling data analysis, process optimization, and predictive maintenance.

Wide Application Range: Web guiding systems find applications in various printing sectors, including labels, packaging, newspapers, and more. They are compatible with different printing technologies, such as flexography, gravure, and offset printing. Furthermore, these systems adapt to a wide range of printing conditions, including varying printing speeds, tension requirements, and web qualities.

In summary, web guiding systems play a crucial role in numerous industrial printing machine applications that rely on continuous web processing to achieve optimal print quality, reducing waste, increasing production efficiency, and ensure smooth operation. As the industry continues to evolve, web guiding systems will play an even more significant role in shaping its future, ensuring optimal performance, and delivering superior print products.