What are the new functions of digital supply chain management?

The purpose of digital supply chain management is to provide enterprises with competitive advantages in the supply chain for digital transformation. Therefore, in addition to having basic supply chain management functions, digital supply chain management should also have the following new functions.

(1) Supply chain digitalization plan. By interconnecting the upstream and downstream of the supply chain, utilizing big data, intelligent learning algorithms, etc., accurately predicting customer demand, integrating and coordinating all operational plans such as product planning, demand planning, procurement planning, production planning, inventory planning, sales planning, etc., and improving the response speed and accuracy of the supply chain.

(2) Digital procurement management. By digitizing the supply chain collaboration center, the procurement business process can be improved, linking procurement with other links to improve procurement efficiency and reduce procurement management costs. In addition, through the collection and big data analysis of consumers' information on websites, forums, official accounts, microblogs, and other channels, the procurement scheme is optimized.

(3) Digital logistics. Transforming the logistics model into a new model that integrates online data flow and offline physical flow through data-driven upstream and downstream processes, as well as assisted decision-making based on digital technology, completely changing the inventory allocation mechanism in the supply chain; Secondly, by utilizing digital technology and intelligent logistics facilities and equipment, optimizing warehousing and distribution processes, improving logistics efficiency, and enhancing supply chain agility.

(4) Intelligent optimization and collaborative decision-making. It refers to the modeling, optimization, and decision-making of supply chain systems based on digital technology, including process optimization, network optimization, inventory optimization, path optimization, coordination decision-making, etc. Intelligent optimization and collaborative decision-making are important manifestations of intelligent supply chain management.

(5) Supply chain data management. Data is digital knowledge and information. Supply chain data management includes data collection, organization, and analysis throughout the entire supply chain, as well as in-depth data mining. The results of data management provide a data foundation for supply chain planning, optimization, and decision-making, promoting the visualization of the supply chain decision-making process.

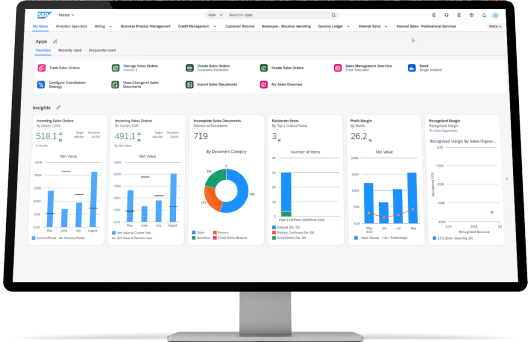

(6) Supply chain digital platform. The digital supply chain platform mainly includes multiple levels, including the application layer, platform layer, and data layer. The application layer customizes supply chain business processes and management functions based on user needs; The platform layer provides modeling analysis, various supply chain models, and data management functions; The data layer provides relevant data throughout the entire supply chain. The digital supply chain platform is interconnected with internal and external systems of enterprises, achieving the convergence of upstream and downstream members in the supply network, facilitating the optimization of supply chain business activities, and maximizing the satisfaction of supply and demand balance.