Special Purpose Motors

There are motors customized for specialized industrial operations like Ex motors for hazardous/explosive environments, Inverter duty motors optimized for variable frequency drive applications, brake motors etc.

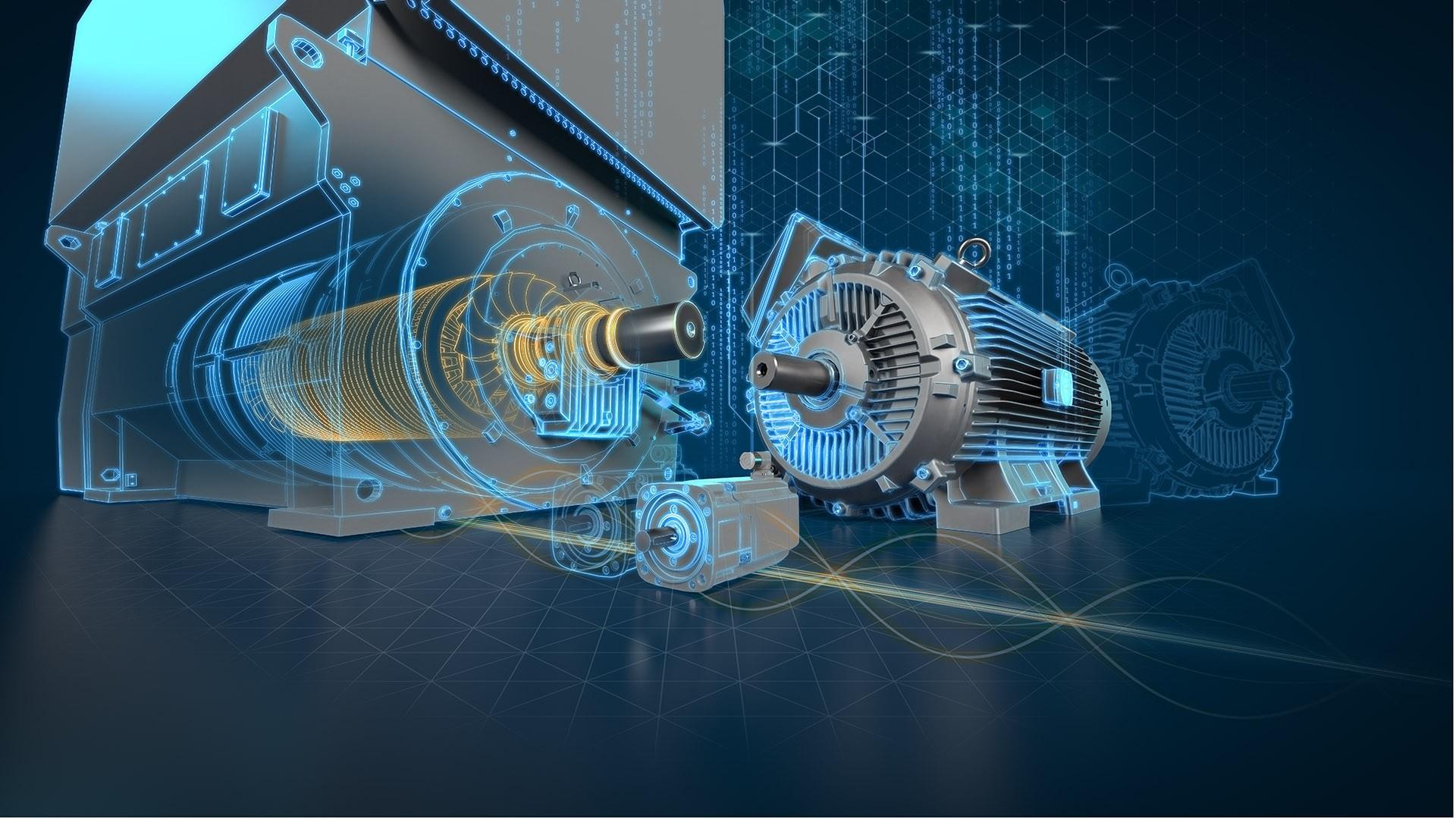

Functioning and Construction of Industrial Motors

All Industrial Motors essentially work on the principle of electromagnetic induction. They convert electrical energy into mechanical energy of rotation through the interaction of magnetic and electric fields.

Industrial motors generally have a robust yet simple construction optimized for continuous heavy-duty operations. The key components are:

- Stator: The stationary outer part made of steel laminations wound with coils of copper wire. It generates a rotating magnetic field.

- Rotor: The inner rotating part which is magnetized either permanently or electrically to interact with the stator magnetic field.

- Shaft: It transfers the torque produced to mechanical load through couplings.

- Bearings: They allow low friction rotation of the shaft. Ball or sleeve bearings are commonly used.

- Housing: Provides enclosing structure and protection to internal components.

- Ventilation: Motors have ventilation ducts to remove heat generated during operation.

Significance of Industrial Motors

Industrial electric motors play a critical role across many industries for the following reasons:

Automation and Mechanization: Motors enable automation by powering all types of production machinery, assembly lines, packaging equipment, conveyor systems etc. This significantly improves process efficiency.

Industrial Motors: The Heart OF Automation AND Manufacturing