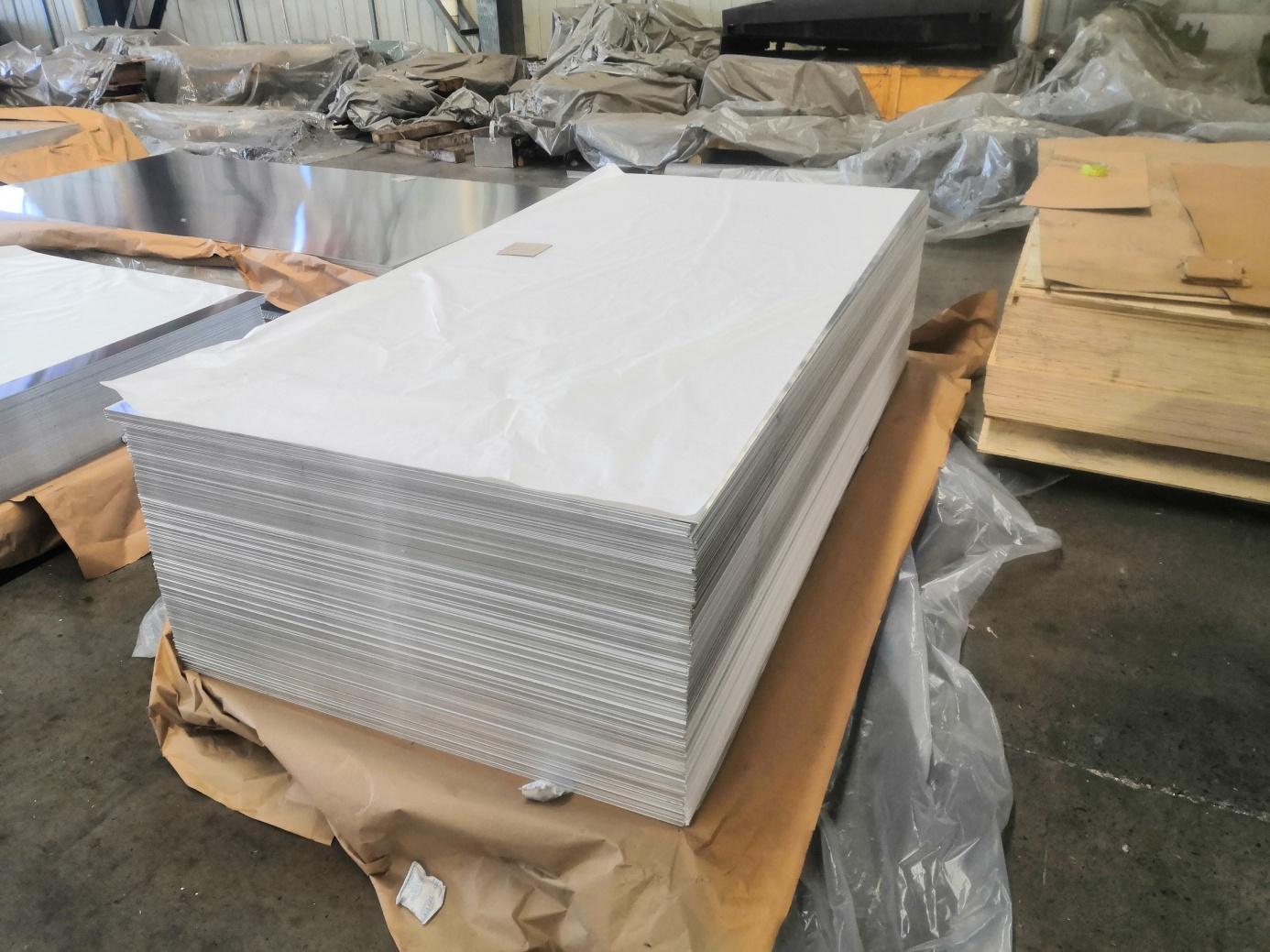

Astm b209 3003 h14 aluminum jacket supplied by using HUAWEI has the functions of corrosion resistant, light weight and long carrier existence. There are a lot of advantages of aluminum jacketing coils, the density of aluminum is small, so the fine of aluminum jacket is light, aluminum jacket sheet roll have the advantages of lovely look, 3003 aluminum sheet plate isn't clean to oxidize within the air, and the carrier life is greatly progressed as compared to different materials.

3003 h14 aluminum jacket astm b209 is a consultant made of 3000 collection aluminum-manganese alloy, so it is also referred to as anti-rust aluminum jacket, that's in particular utilized in thermal insulation materials for pipes, constructing roofs and walls, etc. Generally, 3003 h14 aluminum jacket coil with 0.5mm thickness is used for pipeline thermal insulation. The aluminum jacketing 3003 h14 also can be laminated with different material to improve the overall performance together with poly kraft paper and polysurlyn movie.

The thickness of the aluminum jakcet is commonly primarily based at the diameter of the insulation pipe you're using. The precept is that the smaller the diameter of the pipe, the thinner the thickness of the aluminum jacket. For example, the diameter of the pipe is 100mm, you may use 0.15-0,2mm thickness astm b209 3003 h14 aluminum jacket, the diameter of the pipe is set 500mm, commonly choose 0.Five-zero.7mm thickness aluminum jacketing. In trendy, 1060 aluminum jacketing are extra used, with 60-70% of the occupancy, and aluminum and manganese alloys which include 3003 3004 are selected for coastal initiatives or sturdy acid and high corrosion environments.

Astm b209 3003 h14 aluminum jacket