Rubber gaskets, seals, and O rings are essential components in countless industries, ensuring a tight seal and preventing leaks in various applications. These versatile components are often made from high-quality rubber compounds, offering durability, flexibility, and resistance to various elements.

Understanding Rubber Gaskets and Seals:

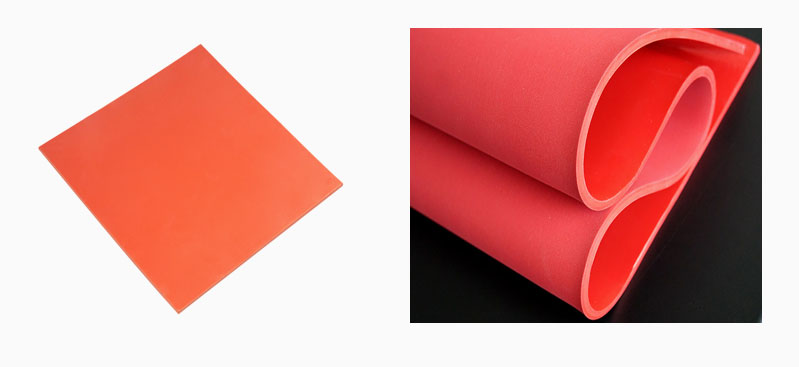

Rubber Gaskets: Flat sheets of rubber, typically cut to specific shapes, used to create a watertight or airtight seal between two surfaces. They are often found in:

- Engines and machinery

- Plumbing and piping systems

- Appliances

- Food processing equipment

- Seals: Similar to gaskets, but with a more intricate shape designed to fit specific grooves or channels. They are commonly used in:

- Doors and windows

- Automotive parts

- Medical devices

- O Rings: Toroidal-shaped rubber rings that provide a circular seal between cylindrical parts. They are widely used in:

- Hydraulic and pneumatic systems

- Engines and pumps

- Industrial machinery

Applications of Rubber Gaskets, Seals, and O Rings:

These versatile components find application in a vast array of industries, including:

- Automotive: Door seals, window seals, engine gaskets

- Aerospace: Seals for aircraft components, fuel systems

- Construction: Roofing materials, window seals, expansion joints

- Food and Beverage: Gaskets for processing equipment, storage containers

- Medical Devices: Seals for syringes, pumps, other medical equipment

Choosing the Right Rubber Products Supplier:

When selecting a supplier for rubber gaskets, rubber seals, and O rings, several factors are crucial:

- Material Quality: Ensure the supplier uses high-grade rubber compounds suitable for your specific application.

- Customizability: Opt for a supplier that offers custom solutions to meet your exact requirements.

- Industry Expertise: Choose a supplier with a strong understanding of your industry’s needs and regulations.

- Quality Control: Verify the supplier adheres to strict quality control standards.