Glass Wafer for Semiconductor Devices Market Analysis, Size, Share, Growth, Trends Forecasts 2023-2030

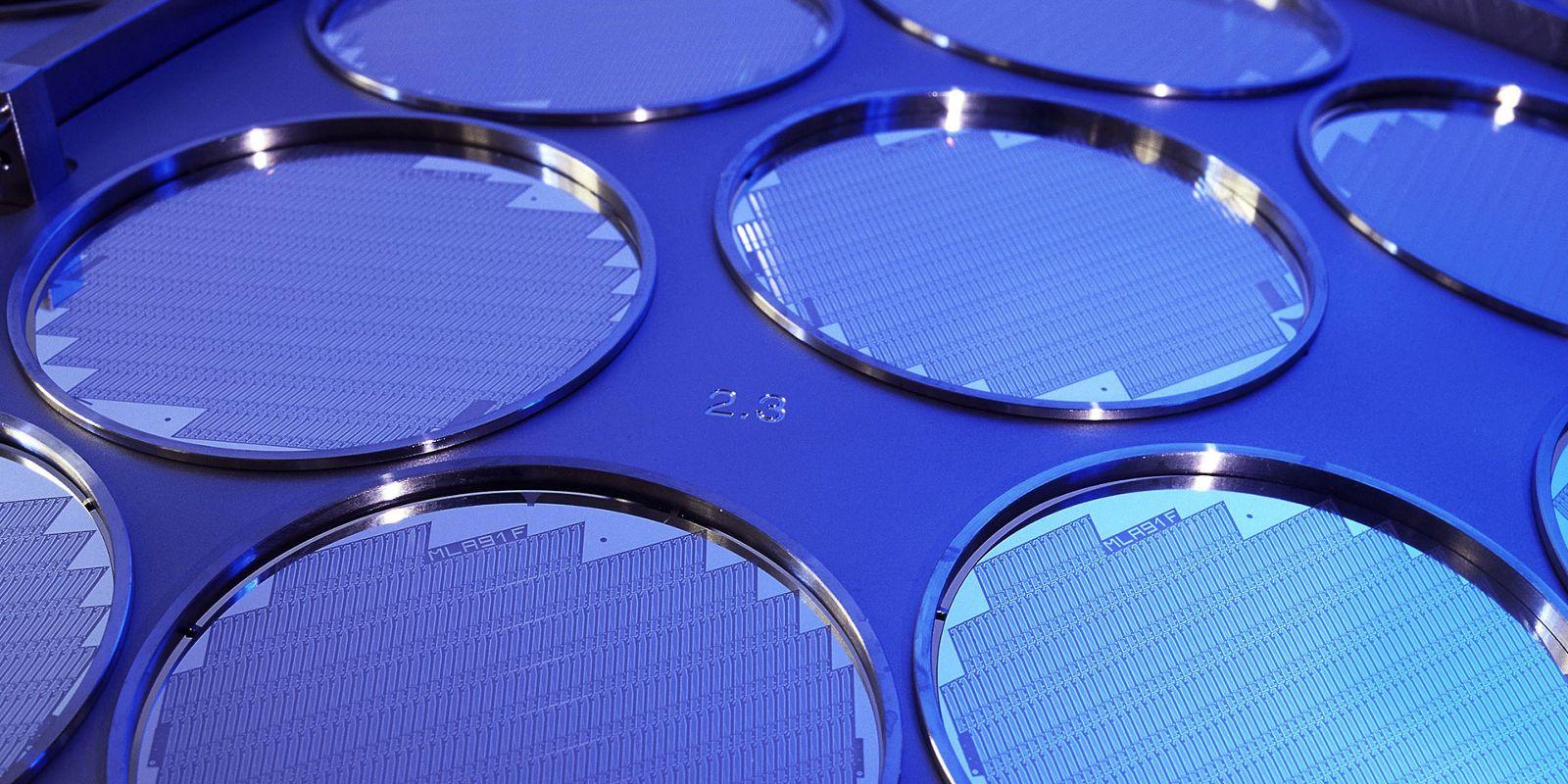

Within the Glass Wafer for Semiconductor Devices market, the industry dynamics are driven by the demand for increasingly smaller and more powerful electronic components. As technological innovation propels the semiconductor sector forward, glass wafers become pivotal in enabling the production of smaller and more efficient semiconductor devices. This market thrives on the perpetual quest for miniaturization and enhanced performance in electronic applications. Glass wafers are an integral component in the production of semiconductor devices like integrated circuits, transistors, and diodes. The silicon semiconductor industry relies heavily on high-quality glass wafers to provide a stable base for manufacturing chips and circuits.

Get Free Sample Report: https://www.metastatinsight.com/request-sample/2580

Top Companies /Key players Glass Wafer for Semiconductor Devices Industry

• Corning Inc.

• Asahi Glass Co., Ltd

• Plan Optik

• Tecnisco Ltd

• Nippon Electric Glass Co., Ltd.

• Samtec

• Dsk Technologies Pte Ltd

• Swift Glass Inc.

• Nano Quarz Wafer

• SCHOTT AG

• WaferPro LLC

Browse Complete Report @ https://www.metastatinsight.com/report/glass-wafer-for-semiconductor-devices-market

The glass wafer begins as a cylindrical boule made from materials like quartz, borosilicate glass, or aluminosilicate glass. These glass formulations possess high uniformity and chemical stability needed for fabricating electronic components. The boule is sliced into thin discs using specialized saws, then polished down to an optically flat and scratch-free surface. These glass wafers serve as the foundational substrate onto which the active layers of a semiconductor device are deposited.

Before device fabrication, glass wafers undergo extremely thorough cleaning and surface preparation. Steps like solvent cleaning, wet chemical etching, and high temperature annealing remove contaminants and enhance the molecular bonding between the glass and deposited films. The purity and integrity of the glass wafer surface is paramount for enabling proper electrical performance and reliability.

Drop us an email at:

[email protected]

Call us on:

+1 214 613 5758

+91 73850 57479

GlassWaferforSemiconductorDevicesMarket, GlassWaferforSemiconductorDevicesMarketIndustry, GlassWaferforSemiconductorDevicesMarketsize, GlassWaferforSemiconductorDevicesMarketshare, GlassWaferforSemiconductorDevicesTrend

Within the Glass Wafer for Semiconductor Devices market, the industry dynamics are driven by the demand for increasingly smaller and more powerful electronic components. As technological innovation propels the semiconductor sector forward, glass wafers become pivotal in enabling the production of smaller and more efficient semiconductor devices. This market thrives on the perpetual quest for miniaturization and enhanced performance in electronic applications. Glass wafers are an integral component in the production of semiconductor devices like integrated circuits, transistors, and diodes. The silicon semiconductor industry relies heavily on high-quality glass wafers to provide a stable base for manufacturing chips and circuits.

Get Free Sample Report: https://www.metastatinsight.com/request-sample/2580

Top Companies /Key players Glass Wafer for Semiconductor Devices Industry

• Corning Inc.

• Asahi Glass Co., Ltd

• Plan Optik

• Tecnisco Ltd

• Nippon Electric Glass Co., Ltd.

• Samtec

• Dsk Technologies Pte Ltd

• Swift Glass Inc.

• Nano Quarz Wafer

• SCHOTT AG

• WaferPro LLC

Browse Complete Report @ https://www.metastatinsight.com/report/glass-wafer-for-semiconductor-devices-market

The glass wafer begins as a cylindrical boule made from materials like quartz, borosilicate glass, or aluminosilicate glass. These glass formulations possess high uniformity and chemical stability needed for fabricating electronic components. The boule is sliced into thin discs using specialized saws, then polished down to an optically flat and scratch-free surface. These glass wafers serve as the foundational substrate onto which the active layers of a semiconductor device are deposited.

Before device fabrication, glass wafers undergo extremely thorough cleaning and surface preparation. Steps like solvent cleaning, wet chemical etching, and high temperature annealing remove contaminants and enhance the molecular bonding between the glass and deposited films. The purity and integrity of the glass wafer surface is paramount for enabling proper electrical performance and reliability.

Drop us an email at:

[email protected]

Call us on:

+1 214 613 5758

+91 73850 57479

GlassWaferforSemiconductorDevicesMarket, GlassWaferforSemiconductorDevicesMarketIndustry, GlassWaferforSemiconductorDevicesMarketsize, GlassWaferforSemiconductorDevicesMarketshare, GlassWaferforSemiconductorDevicesTrend

Glass Wafer for Semiconductor Devices Market Analysis, Size, Share, Growth, Trends Forecasts 2023-2030

Within the Glass Wafer for Semiconductor Devices market, the industry dynamics are driven by the demand for increasingly smaller and more powerful electronic components. As technological innovation propels the semiconductor sector forward, glass wafers become pivotal in enabling the production of smaller and more efficient semiconductor devices. This market thrives on the perpetual quest for miniaturization and enhanced performance in electronic applications. Glass wafers are an integral component in the production of semiconductor devices like integrated circuits, transistors, and diodes. The silicon semiconductor industry relies heavily on high-quality glass wafers to provide a stable base for manufacturing chips and circuits.

Get Free Sample Report: https://www.metastatinsight.com/request-sample/2580

Top Companies /Key players Glass Wafer for Semiconductor Devices Industry

• Corning Inc.

• Asahi Glass Co., Ltd

• Plan Optik

• Tecnisco Ltd

• Nippon Electric Glass Co., Ltd.

• Samtec

• Dsk Technologies Pte Ltd

• Swift Glass Inc.

• Nano Quarz Wafer

• SCHOTT AG

• WaferPro LLC

Browse Complete Report @ https://www.metastatinsight.com/report/glass-wafer-for-semiconductor-devices-market

The glass wafer begins as a cylindrical boule made from materials like quartz, borosilicate glass, or aluminosilicate glass. These glass formulations possess high uniformity and chemical stability needed for fabricating electronic components. The boule is sliced into thin discs using specialized saws, then polished down to an optically flat and scratch-free surface. These glass wafers serve as the foundational substrate onto which the active layers of a semiconductor device are deposited.

Before device fabrication, glass wafers undergo extremely thorough cleaning and surface preparation. Steps like solvent cleaning, wet chemical etching, and high temperature annealing remove contaminants and enhance the molecular bonding between the glass and deposited films. The purity and integrity of the glass wafer surface is paramount for enabling proper electrical performance and reliability.

Drop us an email at:

[email protected]

Call us on:

+1 214 613 5758

+91 73850 57479

GlassWaferforSemiconductorDevicesMarket, GlassWaferforSemiconductorDevicesMarketIndustry, GlassWaferforSemiconductorDevicesMarketsize, GlassWaferforSemiconductorDevicesMarketshare, GlassWaferforSemiconductorDevicesTrend

0 Comments

0 Shares