Sigma Racks is a leading Pan-India provider of high-quality industrial storage solutions. They offer a comprehensive range, including Industrial Storage Racks, Slotted Angle Racks, Pallet Racking Systems, Cantilever Racks, and Mezzanine Floors. Utilizing advanced manufacturing, Sigma Racks meets the diverse storage needs of businesses across India, enhancing warehouse efficiency and organization nationwide

- Male

- Single

- 07/08/1984

- Followed by 0 people

Recent Updates

- How Multi-Tier Racking Systems Boost Storage in Growing Warehouses?

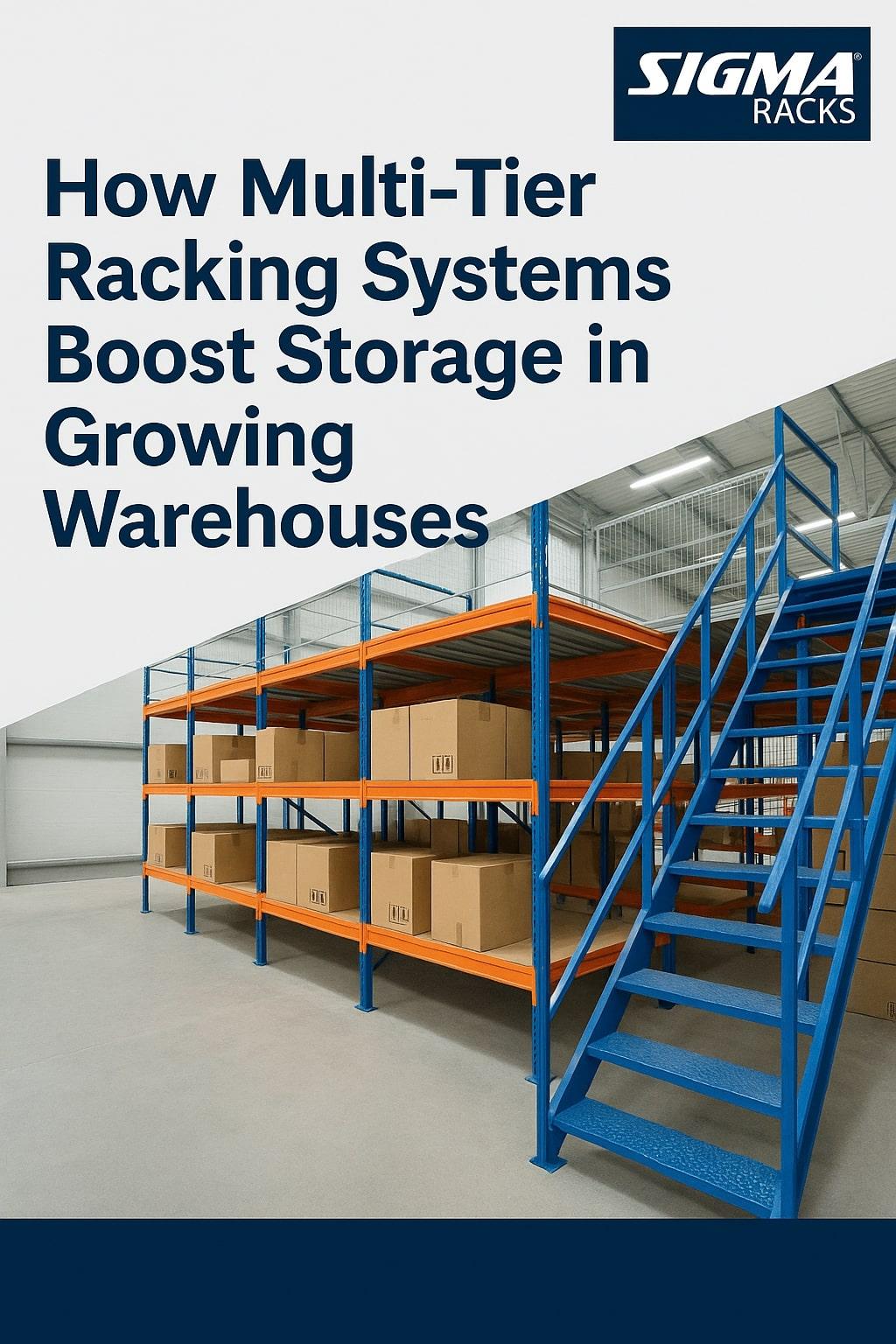

As warehouse operations grow, so does the pressure on available space. Instead of investing in costly expansions or relocating, many businesses are now turning to a smarter solution — multi-tier racking systems.

These systems are built to utilize vertical height by adding multiple rack-supported levels within the same floor space. That means you can literally double or triple your storage capacity without changing the warehouse footprint.

Multi-tier racking systems are ideal for operations that deal with high SKU volumes, seasonal inventory fluctuations, or growing product lines. Each level can be configured for different storage types — from shelving and bins to pallets — making them perfect for order picking, spare part storage, or inventory segregation.

Beyond just space, these systems support faster access, better organization, and safer workflows. With built-in staircases, handrails, and walkways, movement across tiers remains efficient and compliant with safety norms.

Engineered for strength and flexibility, multi-tier systems are modular — which means they can be expanded or reconfigured as the warehouse grows. Whether it's retail, automotive, pharma, or e-commerce, they offer scalable storage without the cost of physical expansion.

If your current setup is running out of space, it might be time to look upward — literally.

@https://sigmastorage.com/warehousing-solutions/multi-tier-cantilever-rack

#MultiTierRacks #WarehouseStorage #StorageSolutions #SmartWarehousing #RackingSystems #WarehouseDesign #SpaceOptimization #SigmaRacks #WarehouseEfficiency #ModularRacks

How Multi-Tier Racking Systems Boost Storage in Growing Warehouses? As warehouse operations grow, so does the pressure on available space. Instead of investing in costly expansions or relocating, many businesses are now turning to a smarter solution — multi-tier racking systems. These systems are built to utilize vertical height by adding multiple rack-supported levels within the same floor space. That means you can literally double or triple your storage capacity without changing the warehouse footprint. Multi-tier racking systems are ideal for operations that deal with high SKU volumes, seasonal inventory fluctuations, or growing product lines. Each level can be configured for different storage types — from shelving and bins to pallets — making them perfect for order picking, spare part storage, or inventory segregation. Beyond just space, these systems support faster access, better organization, and safer workflows. With built-in staircases, handrails, and walkways, movement across tiers remains efficient and compliant with safety norms. Engineered for strength and flexibility, multi-tier systems are modular — which means they can be expanded or reconfigured as the warehouse grows. Whether it's retail, automotive, pharma, or e-commerce, they offer scalable storage without the cost of physical expansion. If your current setup is running out of space, it might be time to look upward — literally. @https://sigmastorage.com/warehousing-solutions/multi-tier-cantilever-rack #MultiTierRacks #WarehouseStorage #StorageSolutions #SmartWarehousing #RackingSystems #WarehouseDesign #SpaceOptimization #SigmaRacks #WarehouseEfficiency #ModularRacks0 Comments 0 Shares1 - When it comes to storing long, bulky, or irregularly shaped items, not all storage systems are created equal. Many warehouses still rely on traditional shelving for everything — but when you're handling materials like pipes, timber, metal bars, or furniture panels, Cantilever Racks are often the smarter and safer option.

While standard shelving works well for cartons and small boxes, it falls short when items don’t fit neatly. In contrast, Cantilever Racks feature horizontal arms that extend from vertical columns, offering open-front storage and easy access for long or heavy items.

One of the biggest advantages of cantilever systems is flexibility. The arm levels can be adjusted, expanded in length, or set up for single or double-sided use. This design not only saves space but also improves material handling safety by minimizing lifting hazards and obstructions.

Whether you’re storing construction materials, furniture pieces, or raw industrial components, it’s important to choose the racking system that fits your inventory — not the other way around.

@https://sigmastorage.com/warehousing-solutions/cantilever-rack

#CantileverRacks #WarehouseStorage #IndustrialShelving #StorageSolutions #OversizedInventory #RackingSystems #WarehouseEfficiency #MaterialHandlingWhen it comes to storing long, bulky, or irregularly shaped items, not all storage systems are created equal. Many warehouses still rely on traditional shelving for everything — but when you're handling materials like pipes, timber, metal bars, or furniture panels, Cantilever Racks are often the smarter and safer option. While standard shelving works well for cartons and small boxes, it falls short when items don’t fit neatly. In contrast, Cantilever Racks feature horizontal arms that extend from vertical columns, offering open-front storage and easy access for long or heavy items. One of the biggest advantages of cantilever systems is flexibility. The arm levels can be adjusted, expanded in length, or set up for single or double-sided use. This design not only saves space but also improves material handling safety by minimizing lifting hazards and obstructions. Whether you’re storing construction materials, furniture pieces, or raw industrial components, it’s important to choose the racking system that fits your inventory — not the other way around. @https://sigmastorage.com/warehousing-solutions/cantilever-rack #CantileverRacks #WarehouseStorage #IndustrialShelving #StorageSolutions #OversizedInventory #RackingSystems #WarehouseEfficiency #MaterialHandling0 Comments 0 Shares1 - Why Do Fast-Moving Warehouses Choose Customized Racking Layouts?

In fast-paced industries like FMCG, e-commerce, and logistics, every second counts. Delays in picking, poor inventory access, or wasted space can slow down operations and eat into profits. That’s exactly why more businesses today are switching to customized racking layouts over generic, one-size-fits-all warehouse racking systems.

A warehouse that handles high volumes needs racking that matches its workflow, inventory type, and movement pattern. Standard pallet racking layouts often fail to support high SKU turnover, irregular packaging sizes, or multi-zone processes. On the other hand, a customized racking layout is built around your actual product flow — from receiving and sorting to dispatch and returns.

At Sigma Racks, we work with businesses to create warehouse storage solutions that not only fit the available space but also support faster picking, vertical stacking, and load-specific durability. Whether it’s combining pallet racks with mezzanine floors, or integrating pigeon hole shelving for small parts — customization improves storage optimization and performance.

@https://sigmastorage.com

#CustomizedRacking #WarehouseOptimization #FastMovingWarehouses #SigmaRacks #StorageSolutions #WarehouseEfficiency #IndustrialRacks #SmartStorage #RackingLayout #PalletRackingSystemsWhy Do Fast-Moving Warehouses Choose Customized Racking Layouts? In fast-paced industries like FMCG, e-commerce, and logistics, every second counts. Delays in picking, poor inventory access, or wasted space can slow down operations and eat into profits. That’s exactly why more businesses today are switching to customized racking layouts over generic, one-size-fits-all warehouse racking systems. A warehouse that handles high volumes needs racking that matches its workflow, inventory type, and movement pattern. Standard pallet racking layouts often fail to support high SKU turnover, irregular packaging sizes, or multi-zone processes. On the other hand, a customized racking layout is built around your actual product flow — from receiving and sorting to dispatch and returns. At Sigma Racks, we work with businesses to create warehouse storage solutions that not only fit the available space but also support faster picking, vertical stacking, and load-specific durability. Whether it’s combining pallet racks with mezzanine floors, or integrating pigeon hole shelving for small parts — customization improves storage optimization and performance. @https://sigmastorage.com #CustomizedRacking #WarehouseOptimization #FastMovingWarehouses #SigmaRacks #StorageSolutions #WarehouseEfficiency #IndustrialRacks #SmartStorage #RackingLayout #PalletRackingSystems0 Comments 0 Shares1 - How Industrial Storage Racks Support India’s Hyperlocal Warehousing Boom?

As India’s quick-commerce sector continues to explode, there’s a growing need for hyperlocal warehouses that can fulfill orders in under 10–15 minutes. Whether it’s groceries, medicines, or daily essentials — brands like Zepto, Blinkit, and Swiggy Instamart rely on compact, high-efficiency storage spaces. That’s where industrial storage racks play a huge role.

Unlike traditional warehouses, hyperlocal hubs operate in tight urban spaces — basements, converted retail units, or small industrial plots. These setups need racking systems that are strong, modular, and space-optimized. At Sigma Racks, our industrial storage racks are custom-designed to match the layout and load requirements of these high-speed fulfillment centers.

From slotted angle racks that fit into narrow corners, to pallet racking systems that utilize vertical space, our solutions help improve picking speed, stock organization, and worker safety — all without needing to expand floor area.

Our racks are also built with automated machinery, ensuring precise build quality, long-term durability, and consistent load performance — crucial for fast-moving inventory and frequent restocking.

Looking to power your hyperlocal or city-based warehouse? Let Sigma Racks help you build it smarter — with racks that perform under pressure

Visit:- @https://sigmastorage.com

#IndustrialStorageRacks #WarehouseSolutions #HeavyDutyRacks #SigmaRacks #SmartStorage #WarehouseEfficiency #RackingSystems #SpaceOptimization #StorageExperts #ModularRacksHow Industrial Storage Racks Support India’s Hyperlocal Warehousing Boom? As India’s quick-commerce sector continues to explode, there’s a growing need for hyperlocal warehouses that can fulfill orders in under 10–15 minutes. Whether it’s groceries, medicines, or daily essentials — brands like Zepto, Blinkit, and Swiggy Instamart rely on compact, high-efficiency storage spaces. That’s where industrial storage racks play a huge role. Unlike traditional warehouses, hyperlocal hubs operate in tight urban spaces — basements, converted retail units, or small industrial plots. These setups need racking systems that are strong, modular, and space-optimized. At Sigma Racks, our industrial storage racks are custom-designed to match the layout and load requirements of these high-speed fulfillment centers. From slotted angle racks that fit into narrow corners, to pallet racking systems that utilize vertical space, our solutions help improve picking speed, stock organization, and worker safety — all without needing to expand floor area. Our racks are also built with automated machinery, ensuring precise build quality, long-term durability, and consistent load performance — crucial for fast-moving inventory and frequent restocking. Looking to power your hyperlocal or city-based warehouse? Let Sigma Racks help you build it smarter — with racks that perform under pressure Visit:- @https://sigmastorage.com #IndustrialStorageRacks #WarehouseSolutions #HeavyDutyRacks #SigmaRacks #SmartStorage #WarehouseEfficiency #RackingSystems #SpaceOptimization #StorageExperts #ModularRacks0 Comments 0 Shares1 - How Warehouse Storage Racks Improve Space and Efficiency in Modern Warehouses?

In today’s fast-paced industrial environment, organized storage is critical for maintaining productivity, safety, and inventory accuracy. One of the key components in efficient warehouse management is the use of high-quality warehouse storage racks that allow businesses to make the most of their available space.

From pallet racking systems and slotted angle racks to heavy duty storage solutions, modern racking systems are designed to handle a wide range of inventory types and load capacities. These racks help reduce clutter, speed up item retrieval, and lower the risk of damage or accidents in the workplace.

An increasing number of Indian manufacturers are offering customized racking systems tailored to specific warehouse layouts and industry needs. Among them, Sigma Racks has built a strong reputation for delivering durable and reliable storage solutions. Their systems are widely used in manufacturing units, retail warehouses, and logistics hubs across the country.

What sets such solutions apart is the combination of engineering strength, quality materials, and space-saving designs. Investing in the right racking infrastructure not only improves floor utilization but also leads to smoother operations and better inventory control.

For any business planning to upgrade its storage, understanding the benefits of professionally designed industrial storage racks is the first step toward long-term efficiency and growth.

@https://sigmastorage.com

#WarehouseStorage, #IndustrialRacks, #HeavyDutyRacks, #PalletRacking, #SlottedAngleRacks, #WarehouseSolutions, #StorageSystems, #SigmaRacks, #SpaceOptimization, #RackingSystems

How Warehouse Storage Racks Improve Space and Efficiency in Modern Warehouses? In today’s fast-paced industrial environment, organized storage is critical for maintaining productivity, safety, and inventory accuracy. One of the key components in efficient warehouse management is the use of high-quality warehouse storage racks that allow businesses to make the most of their available space. From pallet racking systems and slotted angle racks to heavy duty storage solutions, modern racking systems are designed to handle a wide range of inventory types and load capacities. These racks help reduce clutter, speed up item retrieval, and lower the risk of damage or accidents in the workplace. An increasing number of Indian manufacturers are offering customized racking systems tailored to specific warehouse layouts and industry needs. Among them, Sigma Racks has built a strong reputation for delivering durable and reliable storage solutions. Their systems are widely used in manufacturing units, retail warehouses, and logistics hubs across the country. What sets such solutions apart is the combination of engineering strength, quality materials, and space-saving designs. Investing in the right racking infrastructure not only improves floor utilization but also leads to smoother operations and better inventory control. For any business planning to upgrade its storage, understanding the benefits of professionally designed industrial storage racks is the first step toward long-term efficiency and growth. @https://sigmastorage.com #WarehouseStorage, #IndustrialRacks, #HeavyDutyRacks, #PalletRacking, #SlottedAngleRacks, #WarehouseSolutions, #StorageSystems, #SigmaRacks, #SpaceOptimization, #RackingSystems0 Comments 0 Shares1 - Explore the Future of Storage with Sigma Racks at IWS 2025

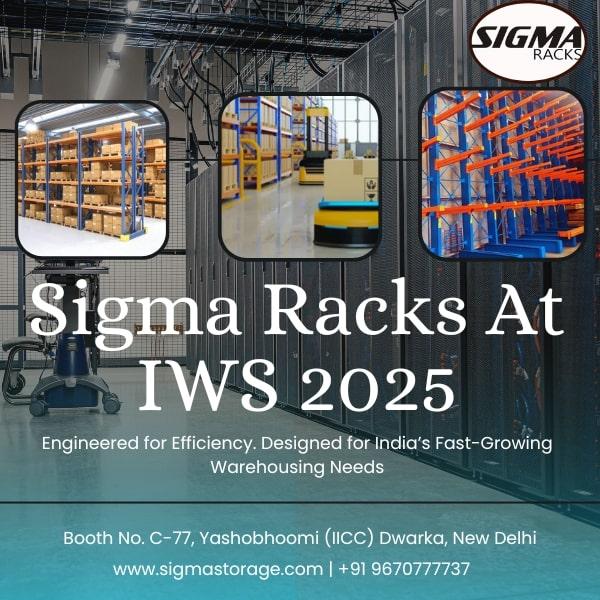

In a country where warehousing and logistics are growing at an unprecedented pace, events like the India Warehousing Show 2025 are becoming more than just exhibitions — they are becoming platforms where change can take place. Sigma Racks is proud to have been a part of this year's event.

Our company is thrilled to announce our participation in this historical event, which will take place at the India International Convention and Expo Centre (IICC) in Dwarka, New Delhi from June 26 to June 28. You can find us at Booth C77, where we'll be showcasing the newest innovations in industrial and warehouse shelving.

Read full blog here:- @https://sigmastorage.com/blog/explore-the-future-of-storage-with-sigma-racks-at-iws-2025

#IndiaWarehousingShow2025, #SigmaRacksBoothC77, #WarehouseRackingSystems, #IndustrialStorageRacks, #MezzanineFloors, #HeavyDutyRacks, #CantileverRacks, #WarehouseAutomationIndia, #WarehouseRackManufacturer, #StorageSolutionsIndia, #WarehouseDesignExpoExplore the Future of Storage with Sigma Racks at IWS 2025 In a country where warehousing and logistics are growing at an unprecedented pace, events like the India Warehousing Show 2025 are becoming more than just exhibitions — they are becoming platforms where change can take place. Sigma Racks is proud to have been a part of this year's event. Our company is thrilled to announce our participation in this historical event, which will take place at the India International Convention and Expo Centre (IICC) in Dwarka, New Delhi from June 26 to June 28. You can find us at Booth C77, where we'll be showcasing the newest innovations in industrial and warehouse shelving. Read full blog here:- @https://sigmastorage.com/blog/explore-the-future-of-storage-with-sigma-racks-at-iws-2025 #IndiaWarehousingShow2025, #SigmaRacksBoothC77, #WarehouseRackingSystems, #IndustrialStorageRacks, #MezzanineFloors, #HeavyDutyRacks, #CantileverRacks, #WarehouseAutomationIndia, #WarehouseRackManufacturer, #StorageSolutionsIndia, #WarehouseDesignExpo0 Comments 0 Shares1 - Cantilever Racks for Better Material Handling in Warehouses

In warehouses that handle pipes, lumber, rods, and other long or irregular items, traditional pallet racks often fall short. That’s where Cantilever Racking Systems offer a major advantage.

Cantilever racks are specifically designed for materials that are too long or bulky for standard shelving. With arms extending outward from a central support column, these racks provide open, unobstructed access from the front — making loading and unloading faster and more efficient.

One of the biggest benefits is improved material handling. Forklift operators can maneuver easily without navigating tight rack columns, reducing handling time and improving safety. For items like steel bars or wooden planks that come in varying lengths, the rack arms can be spaced or adjusted to match the size of the load.

These systems also improve warehouse organization by consolidating long items in a dedicated zone, freeing up space elsewhere and reducing clutter. Their modular design allows for flexibility as inventory changes or grows.

In industries like manufacturing, construction supply, and fabrication, Cantilever Racking Systems are essential for storing long goods while keeping operations smooth and efficient.

@https://sigmastorage.com/warehousing-solutions/cantilever-rack

Cantilever Racks for Better Material Handling in Warehouses In warehouses that handle pipes, lumber, rods, and other long or irregular items, traditional pallet racks often fall short. That’s where Cantilever Racking Systems offer a major advantage. Cantilever racks are specifically designed for materials that are too long or bulky for standard shelving. With arms extending outward from a central support column, these racks provide open, unobstructed access from the front — making loading and unloading faster and more efficient. One of the biggest benefits is improved material handling. Forklift operators can maneuver easily without navigating tight rack columns, reducing handling time and improving safety. For items like steel bars or wooden planks that come in varying lengths, the rack arms can be spaced or adjusted to match the size of the load. These systems also improve warehouse organization by consolidating long items in a dedicated zone, freeing up space elsewhere and reducing clutter. Their modular design allows for flexibility as inventory changes or grows. In industries like manufacturing, construction supply, and fabrication, Cantilever Racking Systems are essential for storing long goods while keeping operations smooth and efficient. @https://sigmastorage.com/warehousing-solutions/cantilever-rack0 Comments 0 Shares1 - Why Pallet Racking Systems Are Essential for Modern Warehouses?

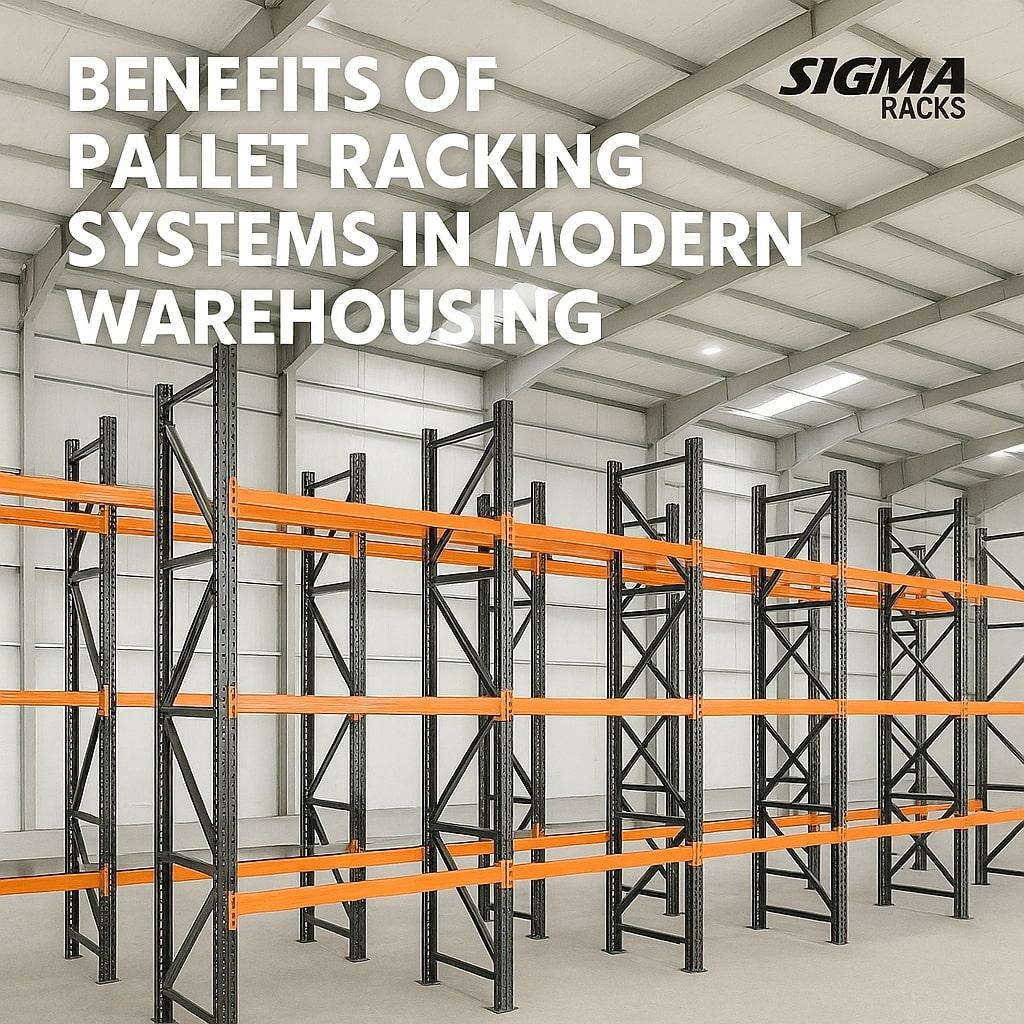

With warehouse operations becoming increasingly complex, smart storage strategies are more important than ever. Among the most efficient solutions used today are Pallet Racking Systems, valued for their durability, versatility, and ability to save space.

These systems enable vertical stacking of palletized materials, helping businesses make the most of available floor area. They also simplify inventory movement — forklifts can load and unload pallets quickly, improving workflow and reducing manual effort.

There are multiple types of pallet racking to fit different warehousing models — from selective racks that provide direct access to each item, to drive-in and push-back systems that optimize space for bulk storage. Each setup is tailored to how frequently items are moved and how densely they need to be stored.

One of the biggest strengths of Pallet Racking is its adaptability. As inventory demands change, these racks can be reconfigured or expanded with minimal hassle. Constructed from strong steel and engineered for heavy loads, they also contribute to safer, more organized work environments.

Overall, pallet racking systems are a practical, scalable way to streamline operations and increase storage capacity in busy industrial settings.

@https://www.sigmastorage.com/product/pallet-racking-system

#PalletRackingSystems, #WarehouseStorage, #IndustrialRacks, #HeavyDutyRacks, #SpaceOptimization, #WarehouseEfficiency, #StorageSolutions, #SmartWarehousing

Why Pallet Racking Systems Are Essential for Modern Warehouses? With warehouse operations becoming increasingly complex, smart storage strategies are more important than ever. Among the most efficient solutions used today are Pallet Racking Systems, valued for their durability, versatility, and ability to save space. These systems enable vertical stacking of palletized materials, helping businesses make the most of available floor area. They also simplify inventory movement — forklifts can load and unload pallets quickly, improving workflow and reducing manual effort. There are multiple types of pallet racking to fit different warehousing models — from selective racks that provide direct access to each item, to drive-in and push-back systems that optimize space for bulk storage. Each setup is tailored to how frequently items are moved and how densely they need to be stored. One of the biggest strengths of Pallet Racking is its adaptability. As inventory demands change, these racks can be reconfigured or expanded with minimal hassle. Constructed from strong steel and engineered for heavy loads, they also contribute to safer, more organized work environments. Overall, pallet racking systems are a practical, scalable way to streamline operations and increase storage capacity in busy industrial settings. @https://www.sigmastorage.com/product/pallet-racking-system #PalletRackingSystems, #WarehouseStorage, #IndustrialRacks, #HeavyDutyRacks, #SpaceOptimization, #WarehouseEfficiency, #StorageSolutions, #SmartWarehousing0 Comments 0 Shares1 - Why Mezzanine Floors Are a Smart Way to Expand Warehouse Storage?

Modern warehouses are constantly under pressure to store more — but expanding physical space isn’t always an option. That’s where Mezzanine Floors come in as a smart, efficient solution.

Mezzanine systems allow businesses to make use of unused vertical height in their facilities. Instead of renting additional storage space or constructing new buildings, companies can add an extra level within the same footprint. This upper level can be used for storing inventory, packaging operations, or even light office setups.

Because Mezzanine Floors are modular, they can be custom-fitted to existing layouts and future storage needs. They’re also scalable — meaning as operations grow, so can the mezzanine structure. Many setups are designed using durable steel frames and grating, offering both strength and flexibility.

Whether it’s an industrial plant, e-commerce hub, or distribution center, mezzanines offer an ideal balance of space optimization and cost-efficiency. With minimal disruption during installation, they’re a fast, practical upgrade for growing businesses.

For businesses looking to maximize space without expanding their footprint, mezzanine flooring is a solution worth considering.

@https://www.sigmastorage.com/warehousing-solutions/mezzanine-system

#MezzanineFloors, #WarehouseStorage, #SpaceOptimization, #IndustrialRacks, #ModularStorage, #WarehouseExpansion, #VerticalStorage, #SmartWarehousingWhy Mezzanine Floors Are a Smart Way to Expand Warehouse Storage? Modern warehouses are constantly under pressure to store more — but expanding physical space isn’t always an option. That’s where Mezzanine Floors come in as a smart, efficient solution. Mezzanine systems allow businesses to make use of unused vertical height in their facilities. Instead of renting additional storage space or constructing new buildings, companies can add an extra level within the same footprint. This upper level can be used for storing inventory, packaging operations, or even light office setups. Because Mezzanine Floors are modular, they can be custom-fitted to existing layouts and future storage needs. They’re also scalable — meaning as operations grow, so can the mezzanine structure. Many setups are designed using durable steel frames and grating, offering both strength and flexibility. Whether it’s an industrial plant, e-commerce hub, or distribution center, mezzanines offer an ideal balance of space optimization and cost-efficiency. With minimal disruption during installation, they’re a fast, practical upgrade for growing businesses. For businesses looking to maximize space without expanding their footprint, mezzanine flooring is a solution worth considering. @https://www.sigmastorage.com/warehousing-solutions/mezzanine-system #MezzanineFloors, #WarehouseStorage, #SpaceOptimization, #IndustrialRacks, #ModularStorage, #WarehouseExpansion, #VerticalStorage, #SmartWarehousing0 Comments 0 Shares1 - Top 5 Warehouse Storage Racks Mistakes & Racking System Fixes

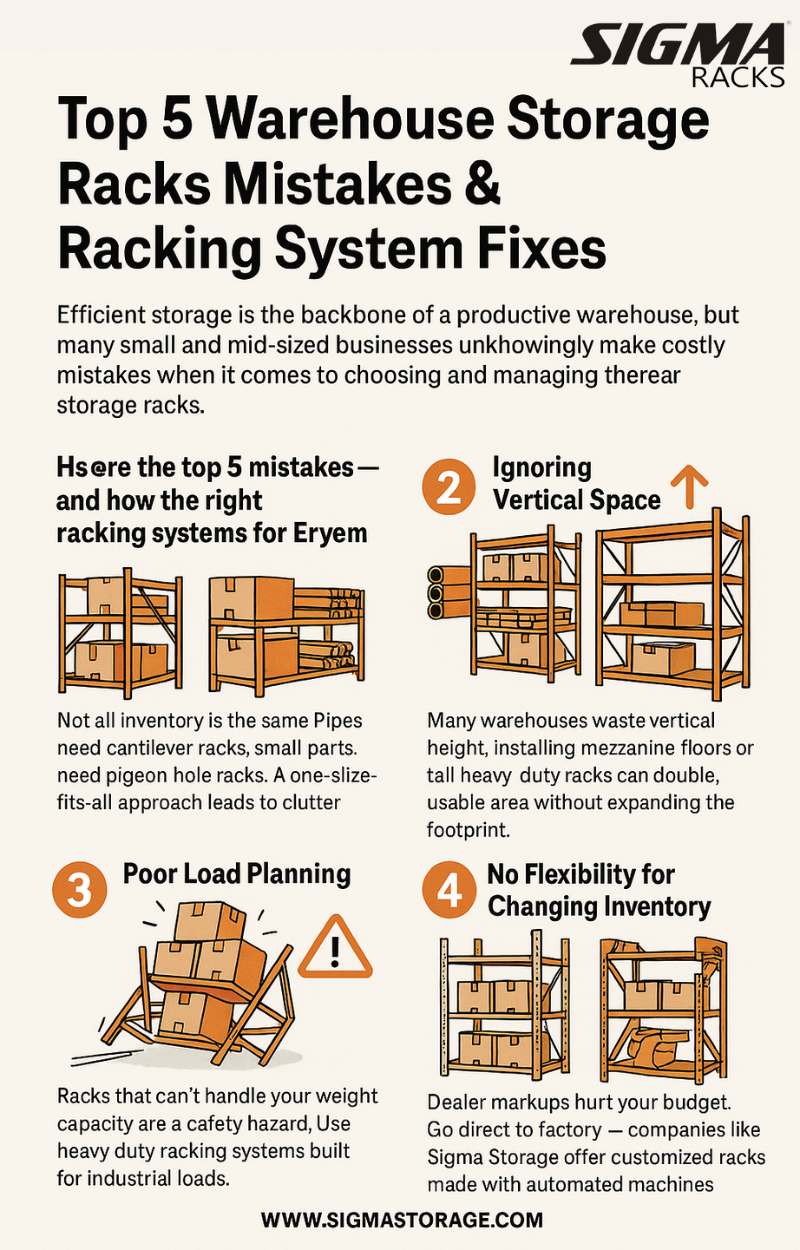

Efficient storage is the backbone of a productive warehouse, but many small and mid-sized businesses unknowingly make costly mistakes when it comes to choosing and managing their Warehouse Storage Racks.

Here are the top 5 mistakes — and how the right racking systems can fix them:

1. Using the Same Rack Type for Everything

Not all inventory is the same. Pipes need cantilever racks, small parts need pigeon hole racks. A one-size-fits-all approach leads to clutter and damage.

2. Ignoring Vertical Space

Many warehouses waste vertical height. Installing Mezzanine Floors or tall heavy-duty racks can double the usable area without expanding the footprint.

3. Poor Load Planning

Racks that can’t handle your weight capacity are a safety hazard. Use Heavy-Duty Racking systems built for industrial loads.

4. No Flexibility for Changing Inventory

Using non-adjustable systems means frequent replacements. Slotted Angle Racks are ideal for modular setups that grow with your needs.

5. Buying from Dealers, Not Manufacturers

Dealer markups hurt your budget. Go direct to the factory — companies like Sigma Storage offer customized racks made with automated machines at the best price.

Avoiding these common mistakes not only boosts safety and efficiency but also maximizes every square foot of your warehouse.

Visit:- @https://sigmastorage.com

#WarehouseStorage, #StorageRacks, #RackingSystems, #IndustrialRacks, #WarehouseSolutions, #HeavyDutyRacks, #SlottedAngleRacks, #MezzanineFloors, #SmartStorage, #SigmaRacks, #WarehouseEfficiency, #InventoryManagement, #SpaceOptimization, #CustomRackingTop 5 Warehouse Storage Racks Mistakes & Racking System Fixes Efficient storage is the backbone of a productive warehouse, but many small and mid-sized businesses unknowingly make costly mistakes when it comes to choosing and managing their Warehouse Storage Racks. Here are the top 5 mistakes — and how the right racking systems can fix them: 1. Using the Same Rack Type for Everything Not all inventory is the same. Pipes need cantilever racks, small parts need pigeon hole racks. A one-size-fits-all approach leads to clutter and damage. 2. Ignoring Vertical Space Many warehouses waste vertical height. Installing Mezzanine Floors or tall heavy-duty racks can double the usable area without expanding the footprint. 3. Poor Load Planning Racks that can’t handle your weight capacity are a safety hazard. Use Heavy-Duty Racking systems built for industrial loads. 4. No Flexibility for Changing Inventory Using non-adjustable systems means frequent replacements. Slotted Angle Racks are ideal for modular setups that grow with your needs. 5. Buying from Dealers, Not Manufacturers Dealer markups hurt your budget. Go direct to the factory — companies like Sigma Storage offer customized racks made with automated machines at the best price. Avoiding these common mistakes not only boosts safety and efficiency but also maximizes every square foot of your warehouse. Visit:- @https://sigmastorage.com #WarehouseStorage, #StorageRacks, #RackingSystems, #IndustrialRacks, #WarehouseSolutions, #HeavyDutyRacks, #SlottedAngleRacks, #MezzanineFloors, #SmartStorage, #SigmaRacks, #WarehouseEfficiency, #InventoryManagement, #SpaceOptimization, #CustomRacking0 Comments 0 Shares1

More Stories